| Home |  |

CMM2000 - On-Line Manual

CMM2000 - On-Line Manual| Cams CMM2000 |  |

This document and diskettes or magnetic tapes contain information as reserved property, protected by the rights of the author. All the rights are reserved.

No part of this book can be reproduced in any form or by any means, or stored in a database or retrieval system, (that is except to be saved as for safety back-up purposes) or translated in other programming languages or in another language without the prior written permission from CAM SOFT s.r.l.

The information contained within this manual is subject to variations without warning.

The rights of this document, and of the diskettes and/or magnetic tapes supplied, is limited only to the reference product, it cannot be copied

and transferred to third parties without the prior consent and written permission of CAM SOFT s.r.l.

CAM SOFT s.r.l. does not provide any warranty in respect of the present material.

This manual is sold as is,without warranty of any kind, either express or implicit, respecting the contents of this manual, including but not limited

to implied warranties for the manual’s quality, performance, merchantability, or fitness for any particular purpose.

CAM SOFT s.r.l. shall not be liableto the purchase or any other person or entity with respect to any liability,

loss or damage caused or alleged to be caused directly or indirectly by this manual.

CAM SOFT s.r.l. declines every responsability derived from errors contained in this manual, or for damages (accidental or not)

derived from the supply, interpretation an use of this manual.

|

|

||

|

|

||

|

|

||

|

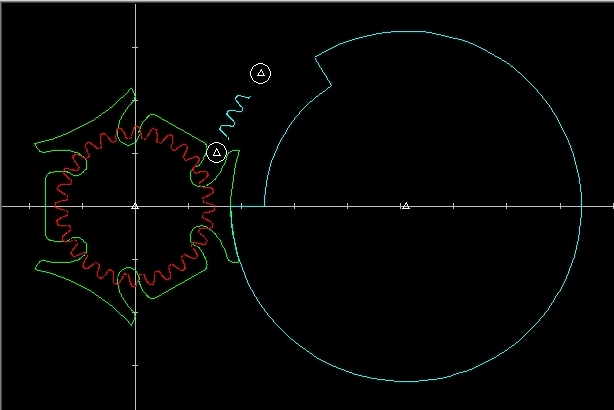

RADIAL Translating OSCILLATING Follower FLAT FACED Follower |

||

|

|

LINEAR Translating OSCILLATING Follower |

|

|

|

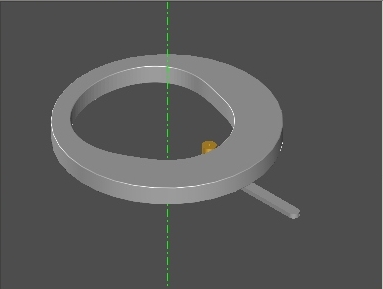

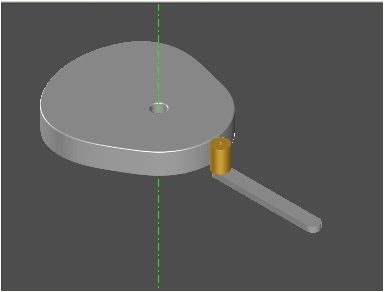

AXIAL Translating OSCILLATING Follower |

|

|

|

||

|

|

||

|

|

SPECIAL PROFILES (Intermittent Working) |

|

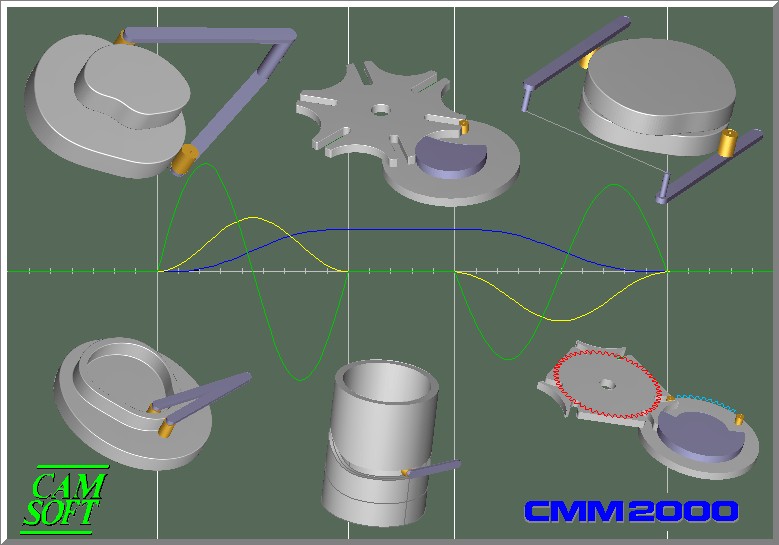

CS CMM2000 is an application oriented to the analysis of Radial Cams , Cylindrical Cams or GENEVA Wheels, STAR Wheels and INTERMITTENT Drum Mechanisms when is known the follower motion.

The design activity consist in the geometric definition of the Cam profile and, as immediate result, the check of the follower operation.

In order to create the Cam curve responding to the y = f(a) coinciding with the required y = f(t) it is supposed that the camshaft rotates at the fixed constant angular velocity ω = 2 π / t (in the case it is α = ω * t)

All the typology of the follower are tacken sthg. into account :

-

RADIAL Translating Follower

-

OSCILLATING Follower

Inside the two Follower typology are taken into account the following Follower types :

-

Roller Follower

-

Flat-faced Follower

-

Knife-edge Follower

It is possible to take into account the Follower constraint obtaining the cam contour either for positive drive or spring load. A part from any structural aspect inside the Cam drawing, CMM2000 gives exclusive reference to the kinematics aspect of the Cam.

The kinematics correlates the attended features of the Follower (position, velocity, acceleration) with those of the mover (Cam profile).

The analysis can follows two way :

-

When it is known the follower Motion Type the Cam profile, correlated with displacement, velocity and acceleration are immediately calculated.

-

When it is known the Cam profile (FILE of POINTS) are verified the Follower kinematics as displacement, velocity and acceleration.

It s necessary therefore to select the Follower type in order to correctly synthesize the Cam profile.

RADIAL Translating Follower

-

Roller Follower

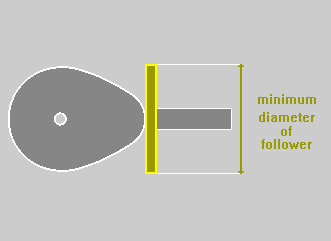

The synthesized profile correspond to the track followed by the centre of the Roller.

The effective Cam profile can be obtained offsetting the synthesized Profile of a quantity

corresponding to the Roller radius or directly using the “Cutter radius Offset” on the CNC. -

Knife-edge Follower

The case is analogous to the previous but the radius of the Follower is “0” -

Flat-faced Follower

The contact point between Cam profile and the flat of the Follower change position continuously in respect to the axis of the Flat-faced Follower. The synthesized profile is generated by the group of the envelope lines of the displacements.

OSCILLATING Follower

-

Roller Follower

-

Knife-edge Follower

-

Flat-faced Follower

Each condition arranges an automatic solution introducing the Cam profile correction when are known the feature of the Cam-Follower group.

The INPUT data, to define the Cam Profile, can to be acquired with some different characteristic as :

1. Basic Curves definition

2. File of points

3. S.V.A. graphic : displacement, velocity and acceleration.

CMM2000 is interfaced with MECAD, a program oriented to kinematic motion analysis, consequently it is directly enabled to read its graphic Files of points S.V.A.

CMM2000 is also enabled to read files CMM of previous versions..

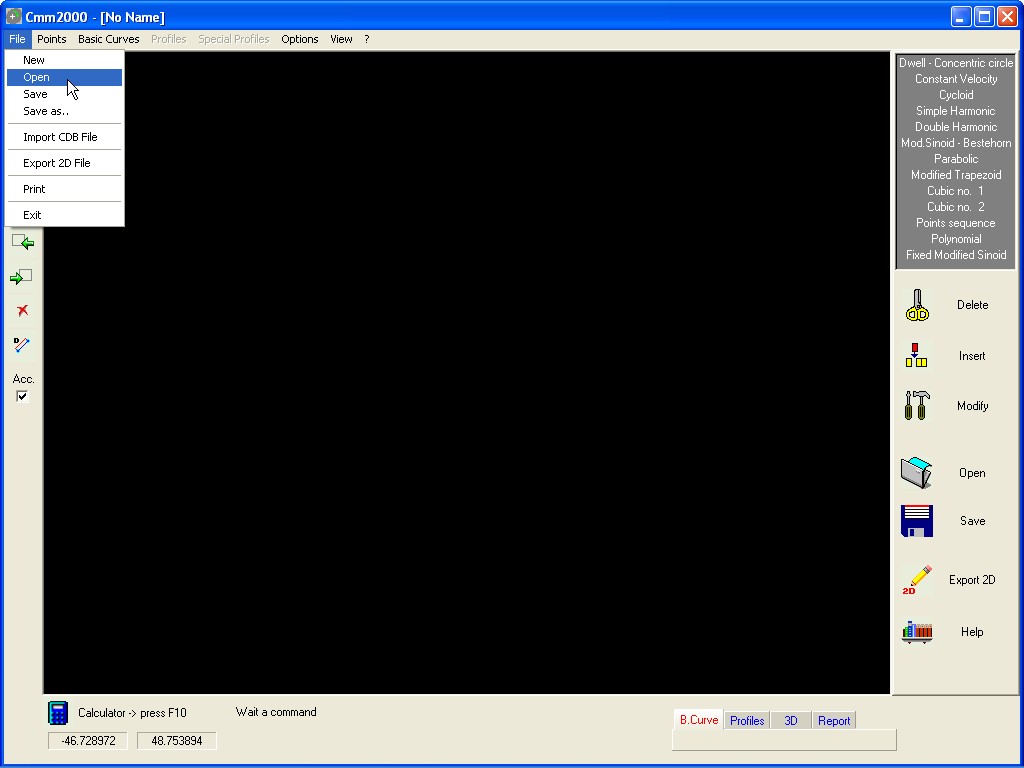

Load a file

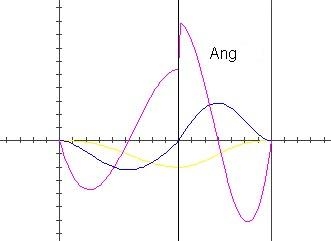

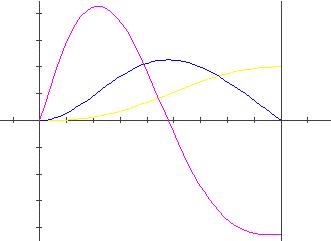

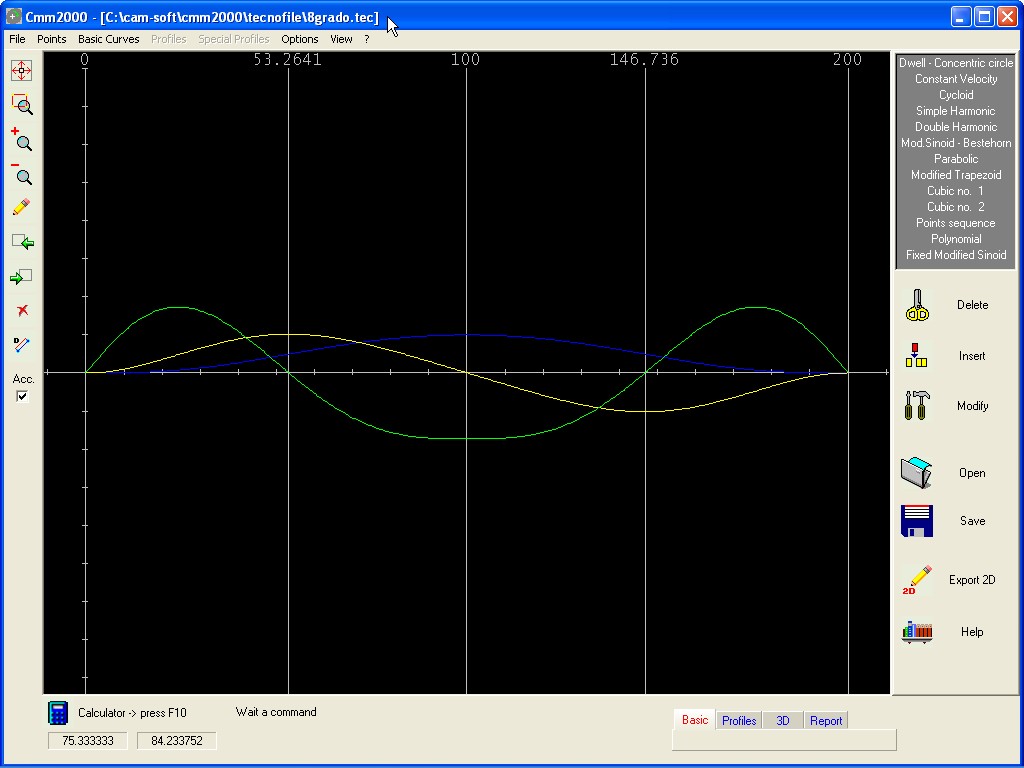

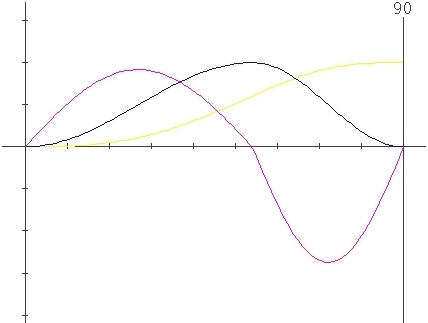

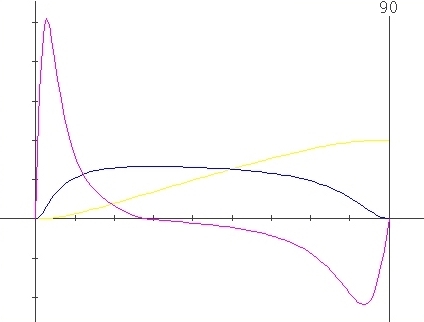

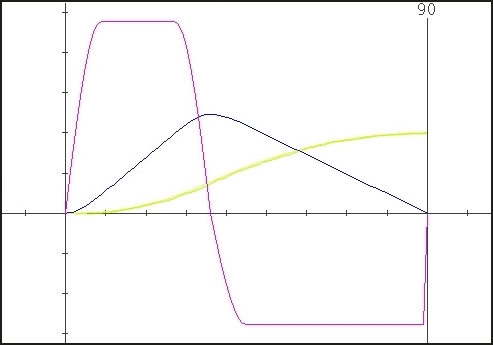

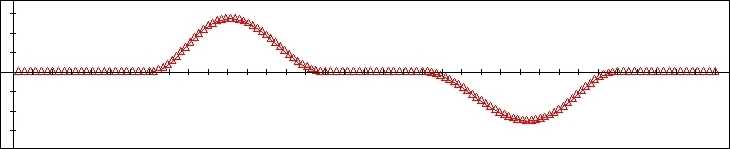

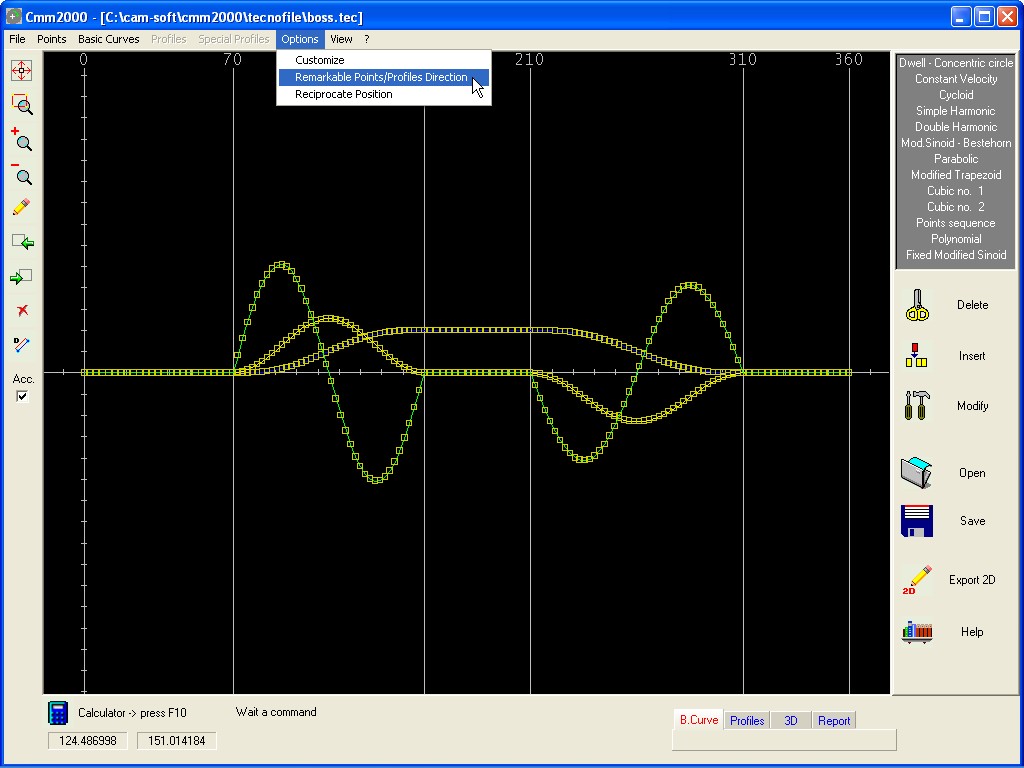

With the introduction of a sequence of Data INPUT the program generates interactively a S.V.A. graphic, with no regard to the characteristics of the Follower and the type of Cam, this graphic will be used afterwards to define the Cam Profile when will be known the structure of the Follower selected and the type of Cam .

Graphic sample of a S.V.A.

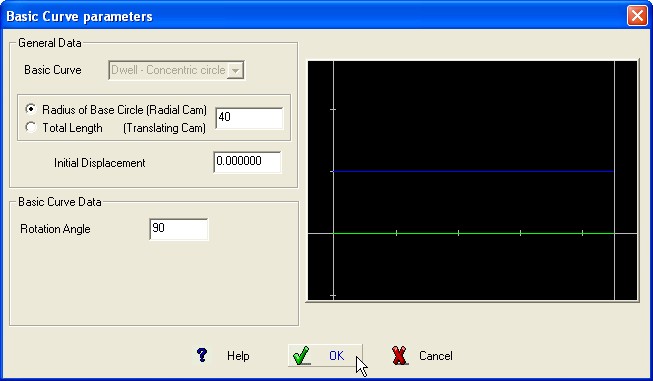

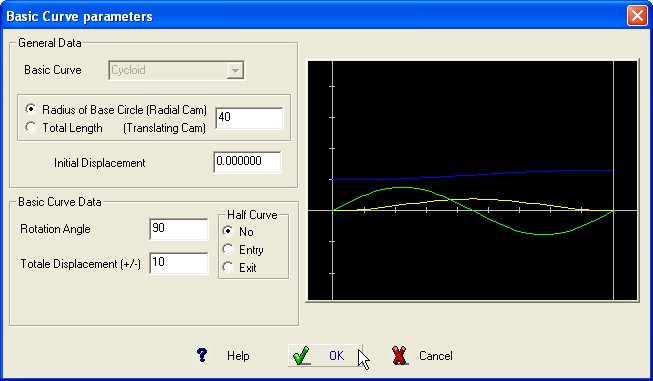

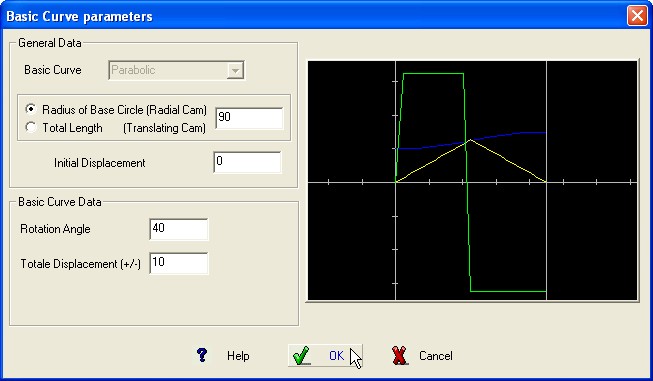

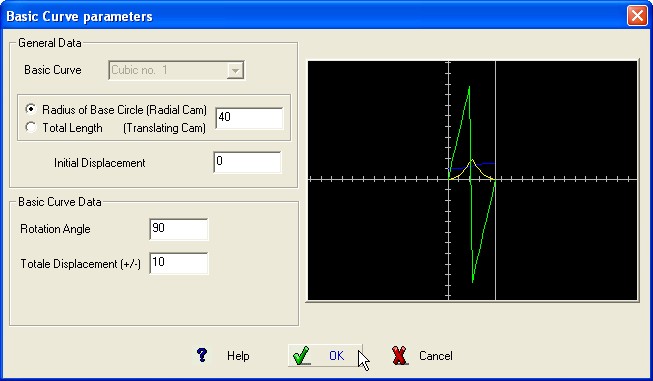

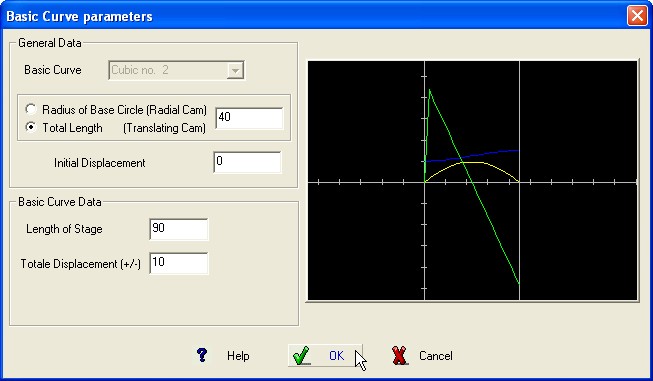

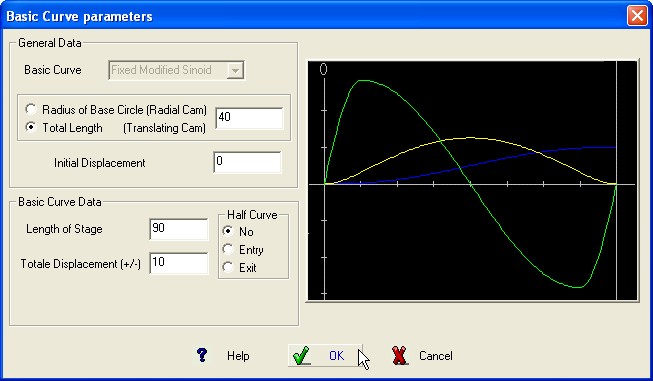

When is inserted the first Basic Curve it is possible to insert the general data of the

Cam which will appears in the upper part

of the

Dialog Box.

The required parameters are (in mm.) :

-

Radius of Base Circle for Radial Cams and Total length for

Translating Cam.

- Initial Displacement ( normally is “0”)

BASIC CURVES definition

Dwell – Concentric circle to the rotation Axes

The activity generate a dwell

stage on the Cam,

it is required the rotation angle.

BASIC CURVE Graphic

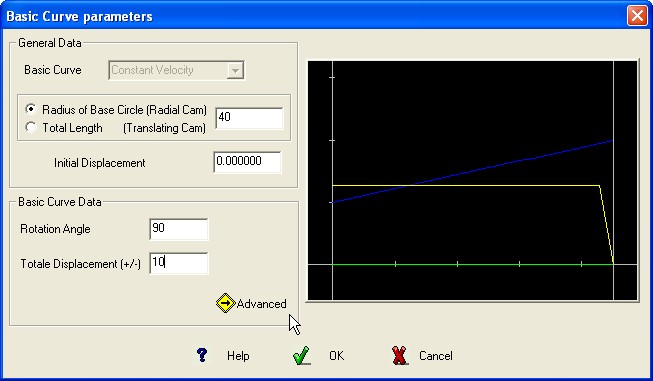

The activity generate a displacement stage

on the

Cam, climb (displacement +) or slope (displacement -) following the

Basic Curve with constant velocity of the follower and zero the

acceleration.

Required Data :

Cam Rotation Angle or length of the stage.

Total displacement of the follower (+/-)

It is suggested to

don’t use this Basic Curve for the first stage, when this is

impossible it is opportune to introduce them with a Dwell–Concentric

circle whose length must be longer than the calculation Step.

BASIC CURVE Graphic

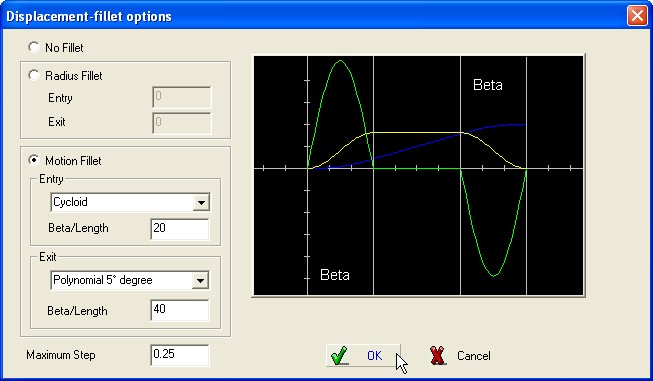

In order to reduce the acceleration peak (initial and final), it is possible insert a displacement-fillet using the Advanced options.

Two options are available :

Fillet with Radius,

fillet with Basic

Curve.

Fillet

with Radius.

Select Radius

and define its value to obtain the

fillet; the

Radius must be greater than the Radius of the roller

follower.

Fillet

with

Basic Curve.

Select the

Basic Curve to be

used,

define the angle Beta representing the width of the stretch of

fillet.

In both cases :

1) The calculus preserves

the position and the slope of the stage at Constant velocity

modifying the entry and exit to insert the fillet.

2) When the

previous Basic Curve lets the permission, it is applied a

transposition of the complete stage, including the fillet, in order

to preserve the start and exit position of the stage at Constant

velocity in respect to the preceding Basic Curve.

The stage at

Constant Velocity has preserved its position and slope while the

fillet covered a part of the preceding Basic Curve.

The

operator will decide to modify the application angle of the

subsequent Basic Curve in order to compensate the part covered by the

exiting fillet.

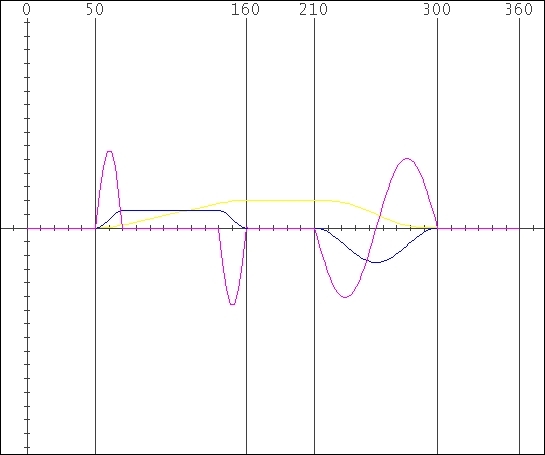

In the following sample are defined five Basic

Curve as :

Stage at Dwell – Concentric circle : 60°

deg.

Stage at Constant Velocity : 90° deg ; displacement 15 mm

; Beta Fillet 20° deg

Stage at Dwell – Concentric circle

: 50° deg.

Stage at Cycloid : 90° deg ; displacement -15

mm

Stage at Dwell – Concentric circle : 60° deg.

The operator can

to notice :

1)

The initial stage at Dwell

is

reduced to 50° deg ; 10° deg are engaged by the fillet.

2)

The stage at Constant Velocity including start

and exit fillet

results 20° deg greater

3)

The second Dwell stage has been defined of 50° deg rather than

60° deg to make room to the exiting fillet.

4)

The subsequent stages preserved their width and position.

Required Data :

Cam Rotation Angle or length

of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

It is possible to define “Half” Basic Curve ; the division point correspond to the inflexion point of the graphic displacement.

Select the Option : No for complete Curve , Entry for entry half-curve and Exit for exiting half-curve

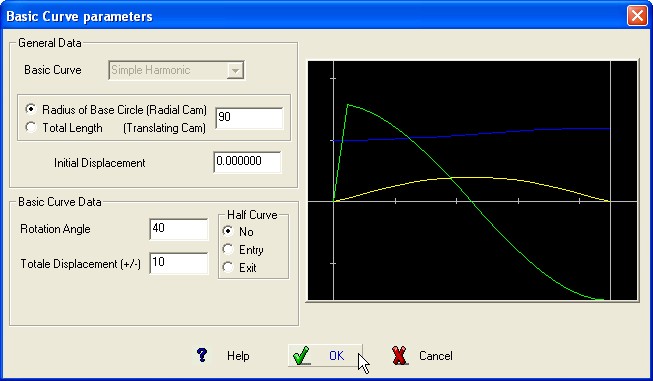

This Curve has a cosine

acceleration curve.

The

projection of a generic radius point P , starting at point “0”

moves vertically at point Q along the diameter D of the reference

circle with simple harmonic motion while the circle rotate at

constant ω.

Required Data

:

Cam Rotation Angle or length of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

It is possible to define “Half” Basic Curve ; the division point correspond to the inflexion point of the graphic displacement.

Select the Option : No for complete Curve , Entry for entry half-curve and Exit for exiting half-curve

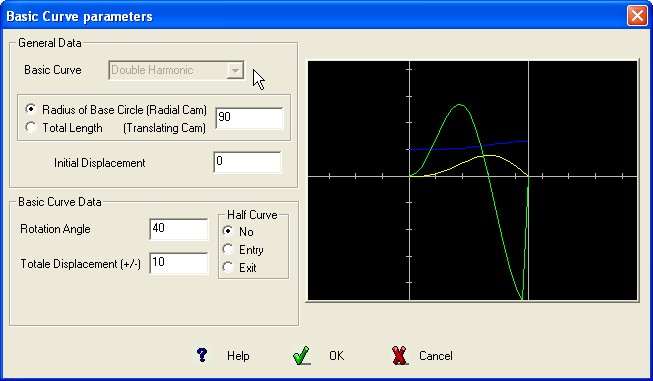

This is an asymmetrical curve composed of two different harmonic motions, one being one-quarter of the amplitude and twice the frequency of the other.

It has the advantages of the simple

harmonic curve

with almost complete elimination of the high shock and vibration at

the beginning of the stroke.

Required Data :

Cam

Rotation Angle or length of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

It is possible to define “Half” Basic Curve ; the division point correspond to the inflexion point of the graphic displacement.

Select the Option : No for complete Curve , Entry for entry half-curve and Exit for exiting half-curve

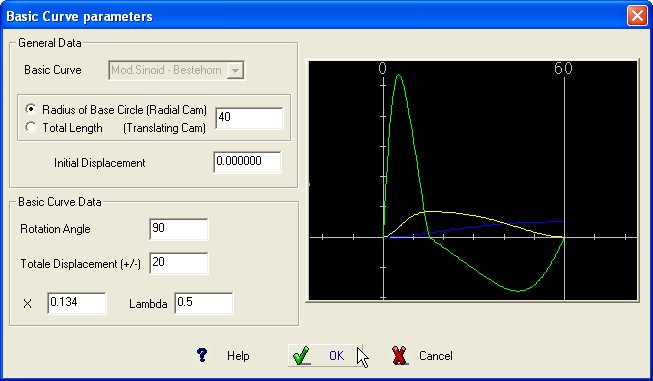

This is a modifiable sinoid using two

supplementary

parameters enabled to move the inflexion point of the graphic

displacement and the position of the maximum acceleration

value.

Required Data :

Cam Rotation Angle or length of

the stage.

Total displacement of the follower (+/-)

X parameter

Lambda (l) parameter

BASIC CURVE Graphic

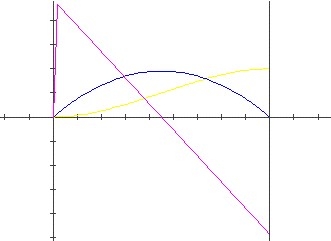

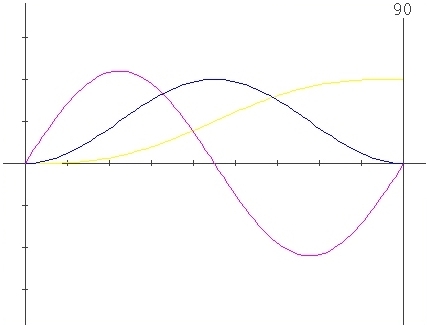

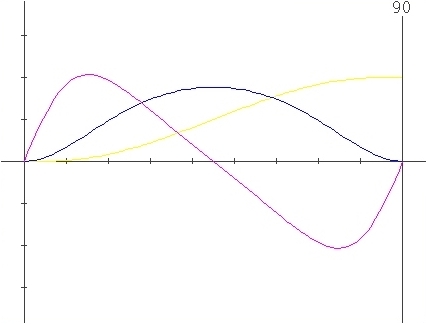

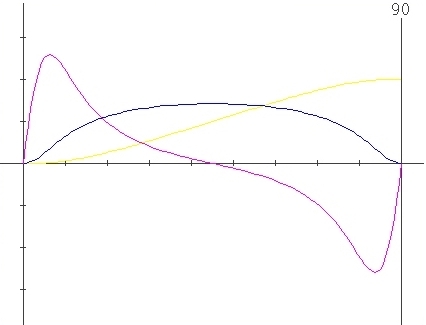

The following graphics show

the changes in

S.V.A. graphics enabled by the change of the parameters X and Lambda

values.

Change for X

only :

Parameters

: X=0 , l=0.5

Parameters

: X=0 , l=0.5

Parameters

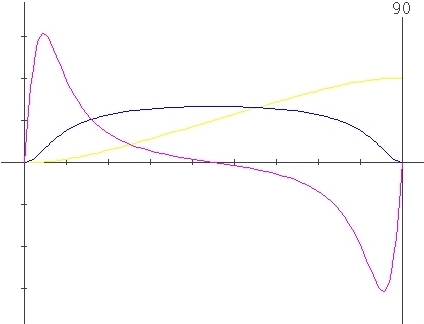

: X=0.134 , l=0.5

Parameters

: X=0.134 , l=0.5

Parameters

: X=0.41 , l=0.5

Parameters

: X=0.41 , l=0.5

Parameters

: X=0.5 , l=0.5

Parameters

: X=0.5 , l=0.5

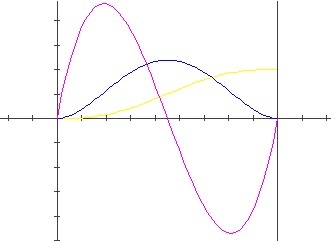

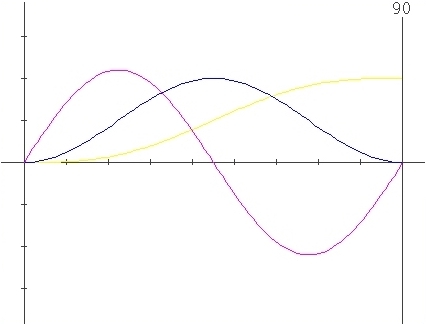

Change for Lambda only :

Parameters

: X=0 , l=0.5

Parameters

: X=0 , l=0.5

Parameters

: X=0 , l=0.3

Parameters

: X=0 , l=0.3

Parameters

: X=0 , l=0.6

Parameters

: X=0 , l=0.6

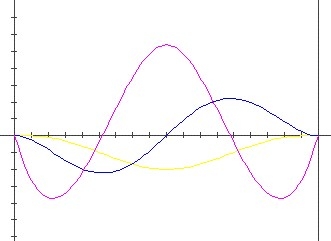

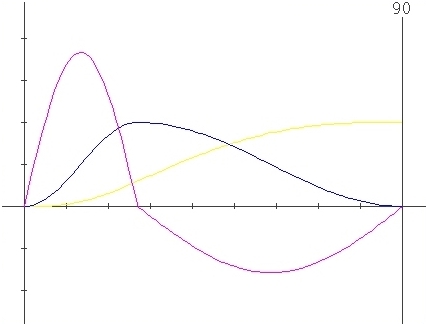

Sample with

simultaneus variation of X and Lambda parameters

Parameters

: X=0.5 , l=0.3

Parameters

: X=0.5 , l=0.3

Parabolic

or constant acceleration

This is

a curve of polynomial family and has constant positive and negative

acceleration values. The curve has the smallest maximum accelerations

for all curves possible.

Required Data :

Cam Rotation Angle or length

of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

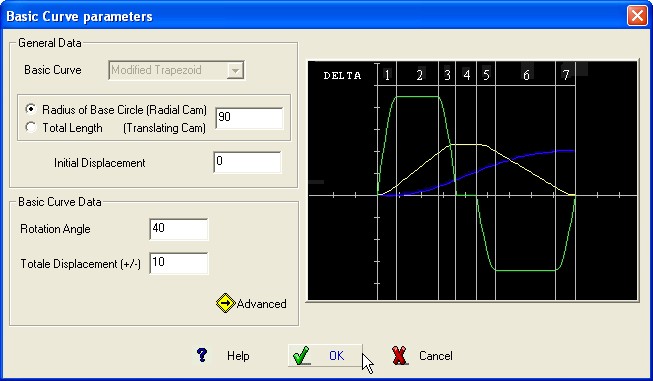

Modified

Trapezoidal

This

is a curve composed of a parabolic motion combined with the cycloidal

curve.

Required

Data :

Cam Rotation Angle or length of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

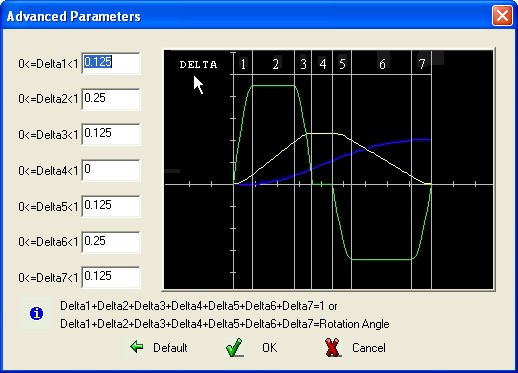

The

“Advanced”

option enable the possibility to define the width of elementary

stages. The default values define a symmetric trapezoidal curve but

it is possible to obtain various configurations changing the

parameters “Delta” defining the seven percentage width of

the elementary stages; instead of “Percentage width” the

operator can use directly the elementary stage amplitude in deg. In

the first case the sum of the elementary Percentage width must be

1.00 , in the second case the sum of the elementary width must be

equal to the total Cam Rotation Angle.

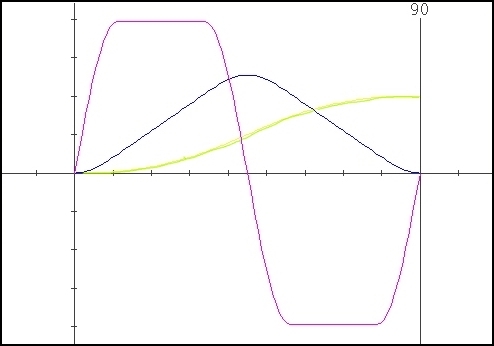

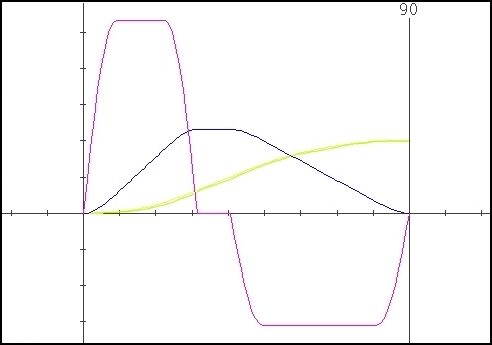

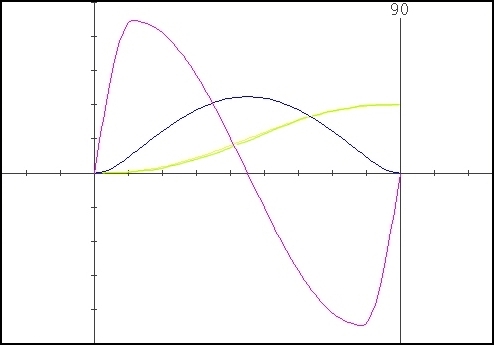

Some samples obtained using different values for the parameter “Delta” :

Cubic

no. 1 Curve

This is a curve

of

polynomial family and has a triangular acceleration curve. It is a

modification of the parabolic curve, eliminating the abrupt change in

acceleration at the beginning and the end of the stroke. However it

does have an acceleration discontinuity at the midpoint.

Required Data :

Cam Rotation Angle or length

of the stage.

Total displacement of the follower (+/-)

BASIC CURVE Graphic

This curve is similar to the Constant

Acceleration

and the Cubic n.1. It differs from these, however, in that there is

no

discontinuity in acceleration in the transition point and also

in that its acceleration is a continuous curve for the complete rise.

Required Data :

Cam Rotation Angle or length

of the stage.

Total displacement of the

follower (+/-)

BASIC CURVE Graphic

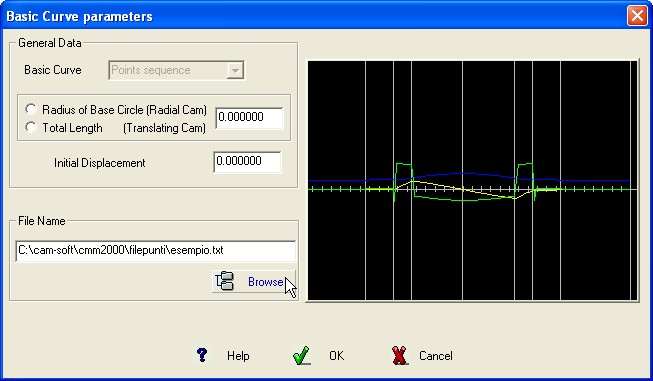

This curve suppose that the operator has a

sequence

of points defining the Cam profile.

The activity requires the

operator to introduce a sequence of coordinates of points, in the

canonic format, defining the profile he will use.

See also the

command of the Menù “Points”

BASIC CURVE Graphic

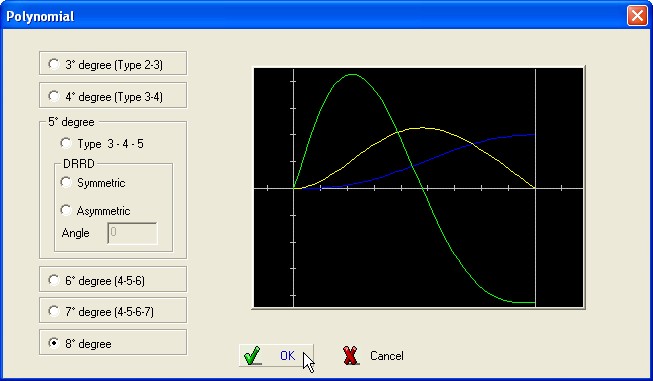

This solution enable the operator to

select one of

the available solution.

Required Data :

Cam Rotation

Angle or length of the stage.

Total

displacement

of the follower (+/-)

It is now necessary to gain access in

“Advanced” to select the Polynomial

Type required.

|

Type 2-3 (3th degree) |

Type 3-4 (4th degree) |

|

Type 4-5-6 (6th degree) |

Type 3-4-5 (5th degree) |

|

Type 3-4-5 (5th degree) DRRD symmetric |

Type 3-4-5 (5th degree) DRRD asymmetric |

|

Type 4-5-6-7 (7th degree) |

8th degree |

It is possible to define “Half” Basic Curve ; the division point correspond to the inflexion point of the graphic displacement.

Select the Option : No for complete Curve , Entry for entry half-curve and Exit for exiting half-curve

The

Fixed Modified Sinoid curve is a combination of two quarter of

cycloidal curve and a complete sinoid curve.

This curve is a good

choice in moving large masses. The modified sine curve, for lower

torque and power demand, is one of the best choice of curves.

BASIC CURVE Graphic

It is possible to define “Half” Basic Curve ; the division point correspond to the inflexion point of the graphic displacement.

Select the Option : No for complete Curve , Entry for entry half-curve and Exit for exiting half-curve

This function enables the

program to import a

File generated with a previous version of CMM

Select

the file to be imported inside the Dialog Box appearing on the

monitor.

When , in the sequence, is requested a File of Point

appears a message requiring the conversion.

In this case use the

command “Convert

from CMM”

in the menù Points

and repeat the operation.

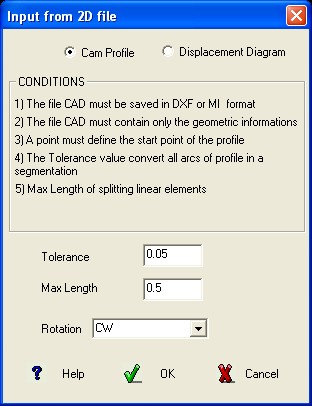

This function enables the

program to obtain the

Follower motion characteristics from any profile saved in DXF or MI

format.

The file CAD must contain only the geometric informations

of the profile completed with a point defining the start point of the

profile.

( the files C:\cam-soft\cmm2000\cad\dxf

\Rettangolo.dxf and

C:\cam-soft\cmm2000\cad\mi

\Policentrica.mi are

useful

examples).

Click the option “Graphic displacement”

when the drawing MI or DXF already expresses the displacement trend

of the follower and not the shape of the Cam (see the file

C:\cam-soft\cmm2000\cad\mi

\Alzate.mi ).

Insert the required data

specifying the chordal

tolerance to be used to convert all the circle arcs in a

segmentation, the max distance from two adjacent points and the

direction to follow the profile.

Using the graphic obtained for

V.S.A. it is now possible to define the shape of the Cam when are

known the complete characteristics of the follower.

Example

: Cam obtained from the file Rettangolo.dxf.

Using the

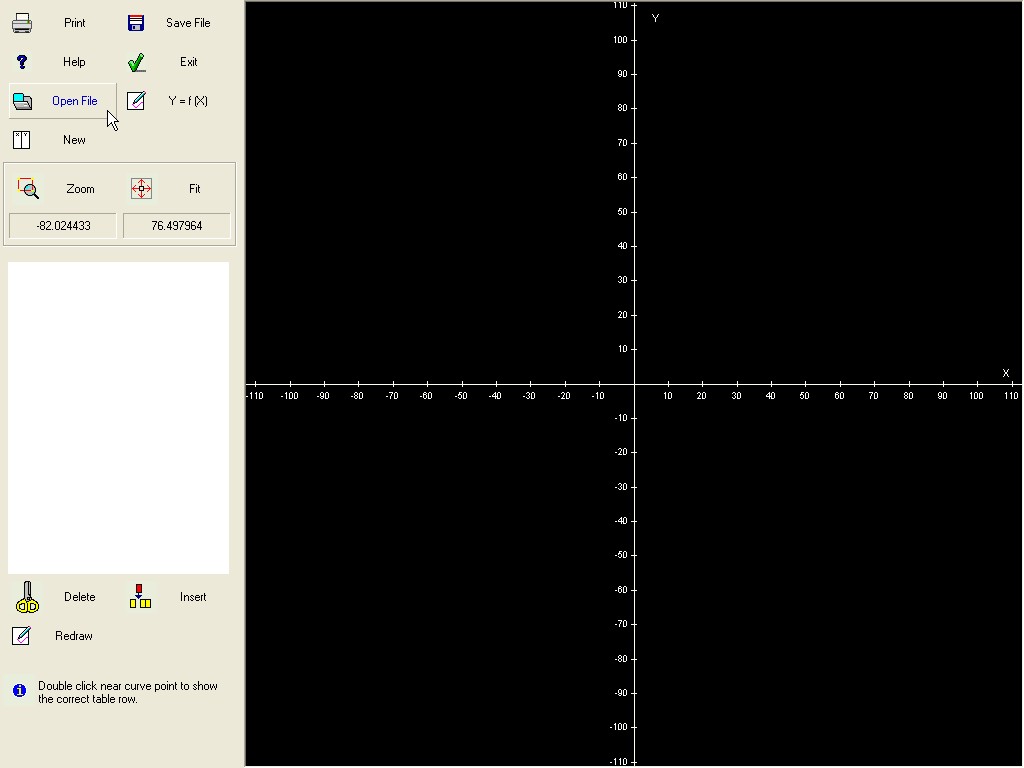

command Create/Modify inside the menù Points

is

gained the access to the windows enabled to operate on Files of

Points.

It is possible to Edit an existing File or create a

new using the command “NEW” or “Y=FUN(X)”

Operations on File of Points

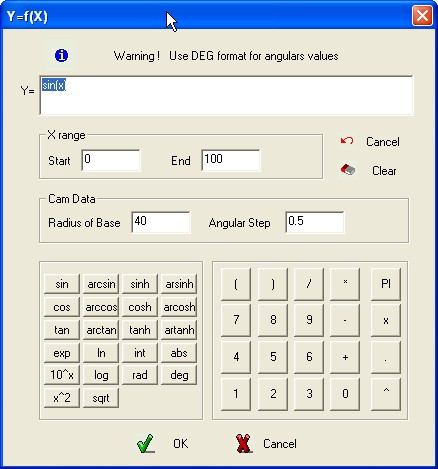

Enable the Operator to insert

a mathematics

function to generate the point of the file.

Example

: Y=SIN(X).

Y=f(X)

Are required : The

value of Radius of Base , the value of starting assigned to the

independent variable and the value final assigned to the independent

variable.

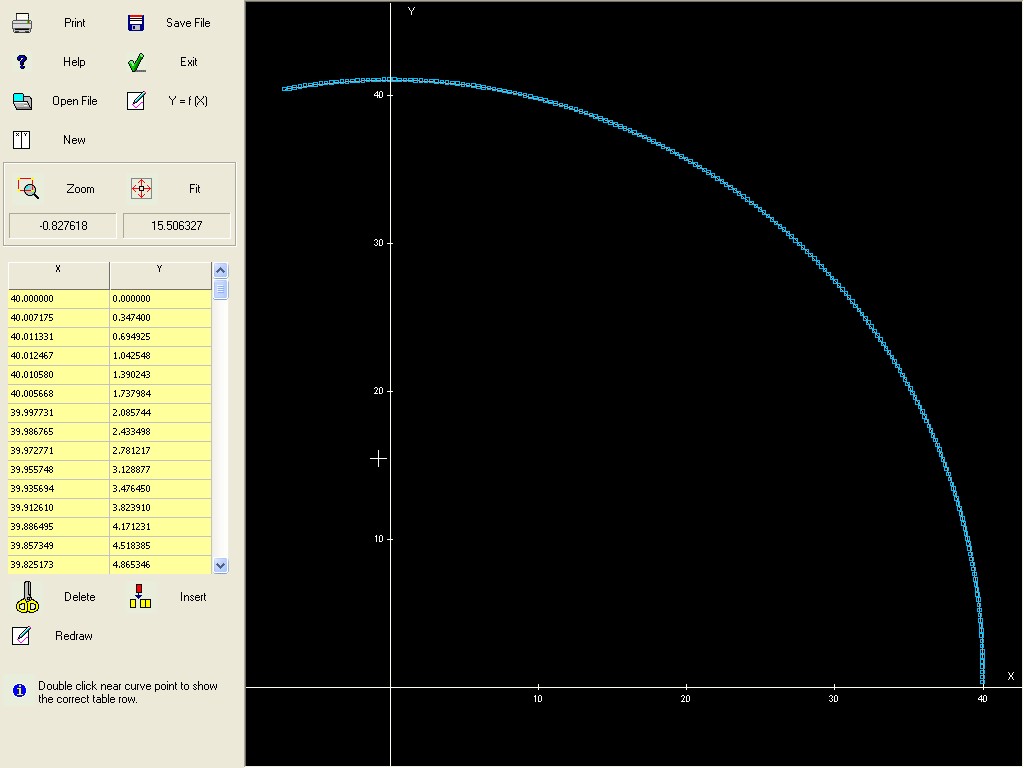

When a File is loaded or created as new, the

coordinates are graphically presented, it is possible to modify the

values acting on the commands appearing at the left of the window.

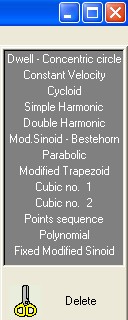

MENU’ BASIC CURVES

(Top

bar)

This Menù enables the command consenting to modify or

change the defined Basic Curves.

Available

Options

:

DELETE

BASIC CURVE

The

command delete the Basic Curve selected with a click on the S.V.A

graphic included into the application stage.

INSERT

A BASIC CURVE

Click on the S.V.A graphic included into the application

stage before which insert the new Basic Curve.

Select the type of

the new Basic Curve and insert the required data.

MODIFY

THE BASIC

CURVE

Click on the

S.V.A graphic

included into the application stage of the Basic Curve to be

modified, select a new Basic Curve or change the parameters of the

current Basic Curve.

To modify the general data of the Cam click on the graphic S.V.A. of the first Basic Curve; in this case it is possible to modify the Base Radius and the Ramp (Total displacement).

This

Menù enable the possibility to insert one or more point on the

graphics S.V.A.

It

is required the angular position of the new point, immediately the

point is inserted on the graphic of displacement, velocity and

acceleration.

When in the required position already exist a point

the command is ignored.

If after the insertion of some new

point, one or more Basic Curve are modified, the program

automatically calculates the new correspondences on the modified

S.V.A. graphics.

Also in this case when one recalculating

correspondence coincide with an existing angular position coming from

the change of the Basic Curve the command is ignored.

To

cancel the inserted points use the command Delete Point of the same

Menù.

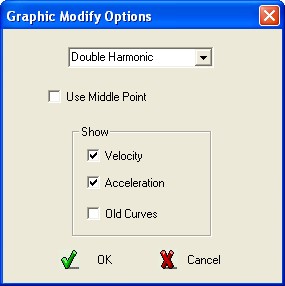

It possible to modify the graphics S.V.A. intervening graphically only on the displayed curve of the displacement. Selecting the command will appear a pull-down menù where may be selected the option :

· Select the Basic Curve to be used into the interval of the modification, are only available Double Harmonic and Cycloid

· May be enabled the selection of the middle point of the interval as pilot-point of the modification

· Select which other curve must be visible (velocity, acceleration) during the modification of the displacement

Confirm the section pressing the key OK, indicate the two extreme point including the modification plus the internal point that will control the interactive modification.

If

no error is contained in the data it possible to drag the curves

included into the selected interval, all the curves will be moved as

congruent rubber-line following the position of the mouse.

It is

possible to interrupt the procedure, in any moment, using the key

![]() ,

to confirm the change

,

to confirm the change

press the left button

of the mouse if the displacement must coincide with the current

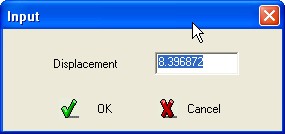

position of the mouse pointer OR the right button of the mouse if it

is requested a precise value of the displacement, in this case will

appear a DialogBox in which write the precise value of the

displacement, press OK to confirm.

Note : Redefining the Basic Curve interested by an interactive modification, the modification will be lost. Instead it is possible to intervene on the previous and following Basic Curve.

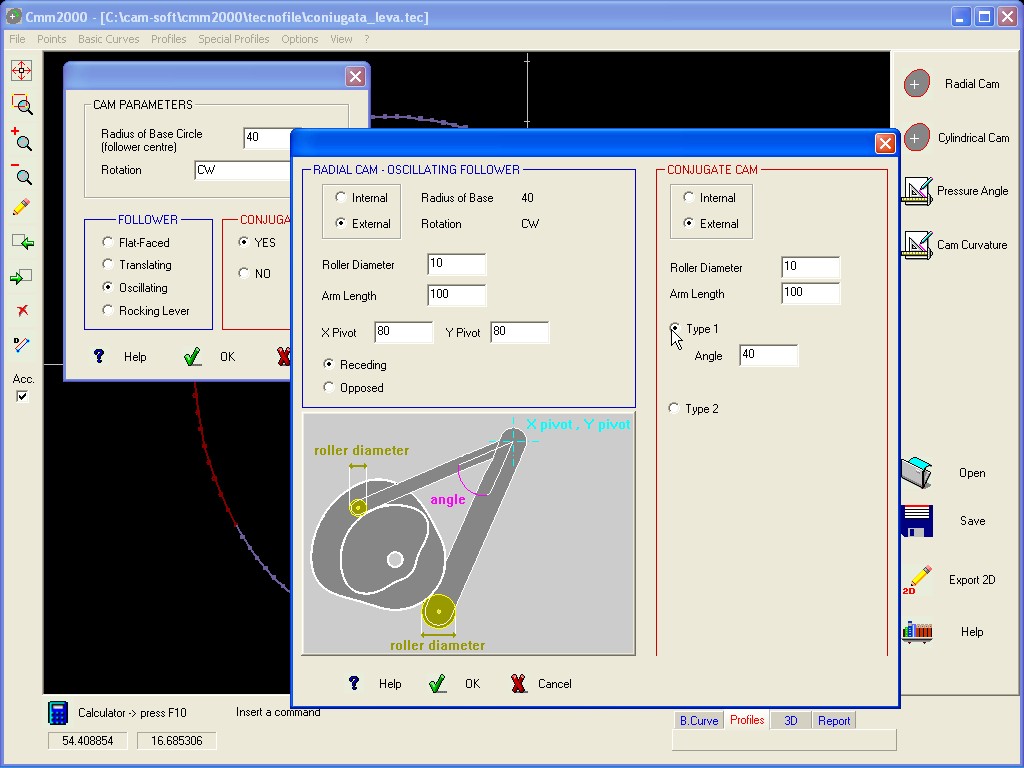

Window Profiles

Inside sub-menù are present the following Options :

RADIAL CAM / TRANSLATING CAM / CYLINDRICAL CAM

Starting from the Data INPUT the Profiles of a Radial Cam,

Translating Cam, Cylindrical Cam are respectively calculated.

Select

the structure of the follower and insert the required Data.

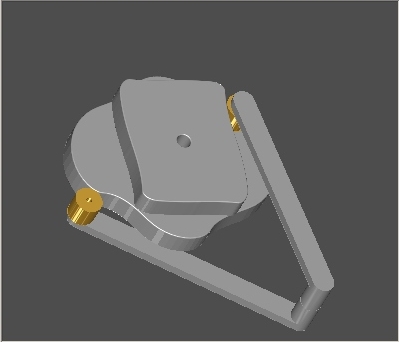

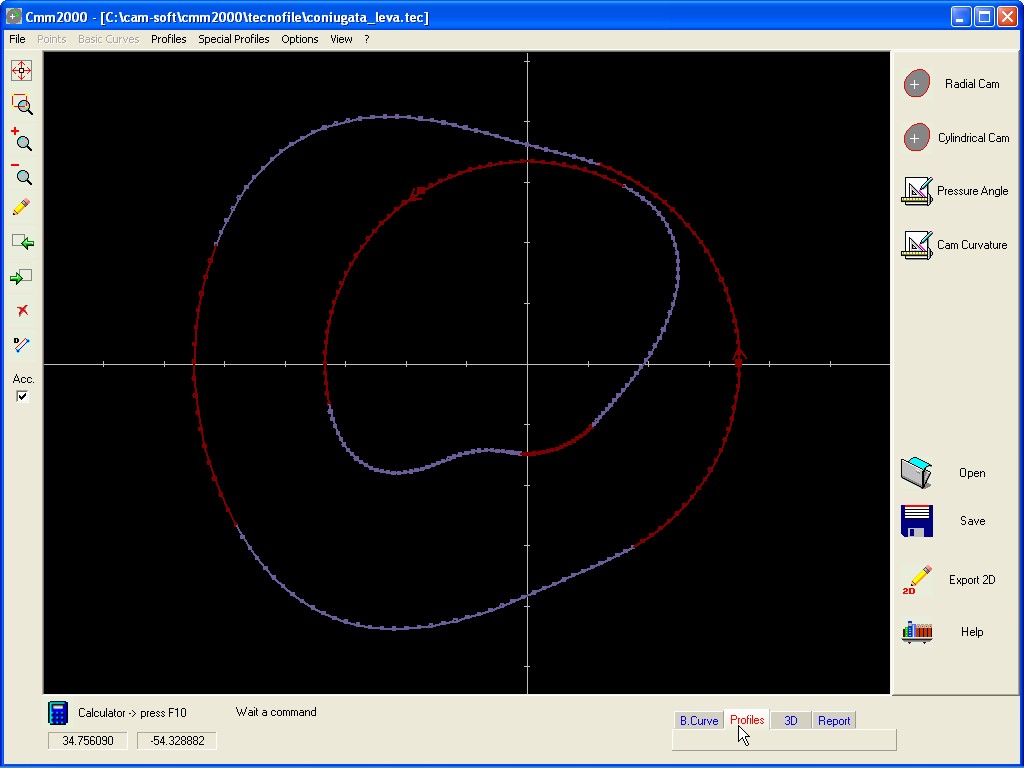

Ex. Radial Cam with OSCILLATING Follower and balancing frame.

CONJUGATE CAM / MISALIGNED FOLLOWER

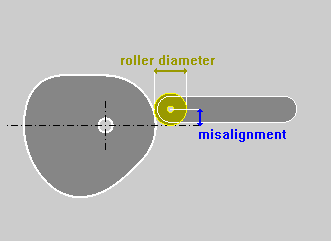

For

a Radial Cam, and where admitted, it is possible to calculate the

Conjugate Cam profile and/or the Cam profile using a misaligned

follower :

RADIAL

Translating

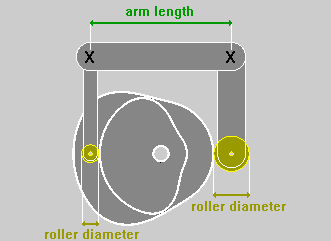

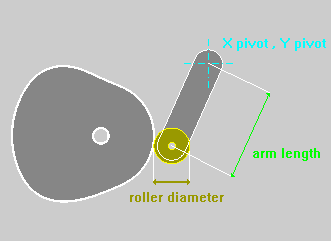

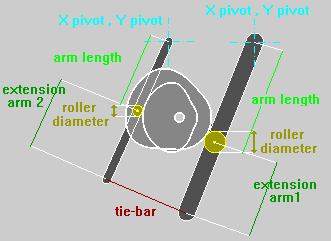

Follower :

OSCILLATING

Follower :

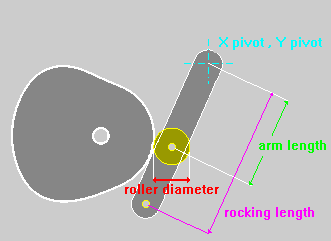

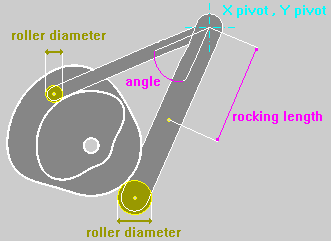

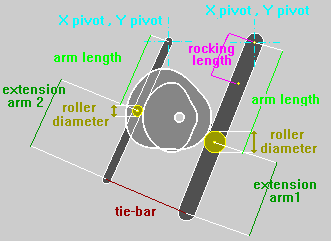

The Option Roking Lever enables the calculus of the Cam Profile inserting the motion characteristics in respect to the point of application of the Follower instead of the point of application of the Roller.

The length of the Roking must be Negative when the point selected for the definition of the motion characteristics is in an opposite position to the Roller in respect to the Pivot Point.

FLAT

FACED Follower :

Selecting

one of the Option : Cam Profile Internal

/ External

it is possible to obtain the Solid

Models as

represented in the

following images.

Internal

Internal

External

External

Coordinating the Type of Cam (Internal / External) with the structure of the frame defining the Conjugate Cam, it is possible to obtain all the types of Desmodromic Cams (external track / internal track, etc.)

“Desmodromic”Cam

defined with Radial Cam

Internal and Conjugate Radial Cam External.

“Desmodromic”Cam

defined with Radial Cam

Internal and Conjugate Radial Cam External.

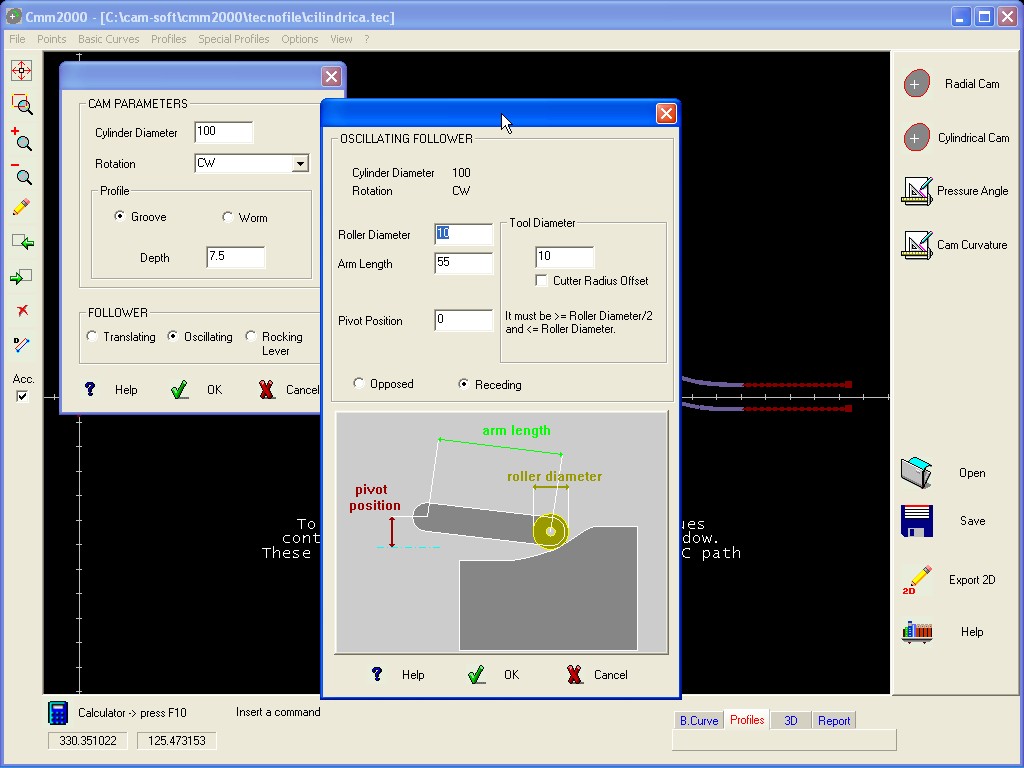

Inside the Dialog Box defining the CYLINDRICAL

CAM it is

possible to define the

Diameter of the Tool and enable / disable the option to use or not

the Cutter Radius Offset on the CNC.

These conditions are used

for Data calculation of the the Tool Path in order to work the Cam on

a CNC machine.

Notes :

For

the case only of Cylindrical Cam with RADIAL

Translating Follower,

worked with a

tool having the same diameter of the Roller it is possible to use the

2D Profile exportable from the window Profiles.

In

all the other cases there are necessary further specific informations

as follows :

Case 1.

The

operator gives : Roller

Diameter = 0

and Tool

Diameter =

0

It is a limit case, it is

generated only a Cam Profile representing the track of the centre of

any Roll for any tool diameter. Inside the window Data

are

presented

the informations regarding the tool centre, used for the CNC in the

format : Angle, X,

Y, Z

The Option : Use

the “Cutter

Radius Offset” has no

effect.

Case 2.

The operator gives : Roller

Diameter ≠ 0 and

Tool

Diameter = Roller Diameter

Inside

the window Profiles will appear two Profiles representing the Upper

Cam Profile and the Lower Cam Profile. Inside the window Data

are

presented

the informations regarding the tool centre, used for the CNC in the

format : Angle, X,

Y, Z

IMPORTANT :

It

is impossible to mill the Cam Profile with a tool having a different

Diameter in respect to the Roller Diameter previously defined.

The

Option : Use

the “Cutter

Radius Offset” has no

effect.

Case

3.

The operator gives : Roller

Diameter ≠ 0 and

Tool

Diameter defined

as follows :

Roller Diameter >

Tool

Diameter > Roller Diameter / 2

The

Option : Use

the “Cutter

Radius Offset” is Disabled

Inside

the window Profiles will appear two Profiles representing the Upper

Cam Profile and the

Lower Cam Profile.

Inside the window Data

are

presented

the informations regarding two tracks for the tool centre,

used

for the CNC in the format :

Angle,

X, Y, Z regarding

the milling of

the lower track of the Cam Profile.

Angle,

X, Y, Z regarding

the milling of

the upper track of the Cam Profile.

IMPORTANT

: It is

impossible to mill the Cam

Profile with a tool having a different Diameter in

respect to the

Tool Diameter previously defined.

The

Option : Use

the “Cutter

Radius Offset” is Enabled

Inside

the window Profiles will appear two Profiles representing the Upper

Cam Profile and the Lower Cam Profile.

Inside the window Data

are

presented

the informations regarding two tracks on the Cam Profile, used for

the CNC in the format :

Angle,

X, Y, P, Q, Z regarding

the

milling of the lower track of the Cam Profile.

Angle,

X, Y, P, Q, Z regarding

the

milling of the upper track of the Cam Profile.

Note

: Since the

Data are regarding the

nominal Track surface of the Cam Profile, it is possible to use any

tool diameter

< Roller Diameter.

It

is also important :

a

) The CNC must

be enabled to

use the function G41, G40, G42 (Enabling Cutter Radius Offset)

jointly the use of a Rotating Axe; in this case use Data in the

format Angle,

X, Y, Z

.

b ) The CNC must

be enabled to

use, in parametric mode,

the values assigned to P

and

Q

indicating

the parametric corrections for X

and Y

;

in this case use Data in the format Angle,

X, Y, P, Q, Z

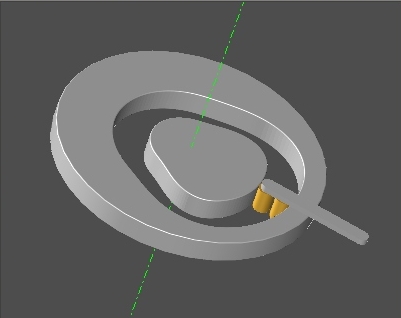

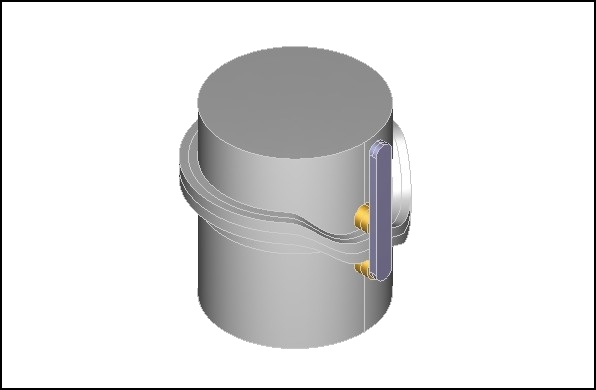

CYLINDRICAL CAM,

AXIAL

Translating

Follower, Rib Cam Profile

CYLINDRICAL CAM,

AXIAL

Translating

Follower, Rib Cam Profile

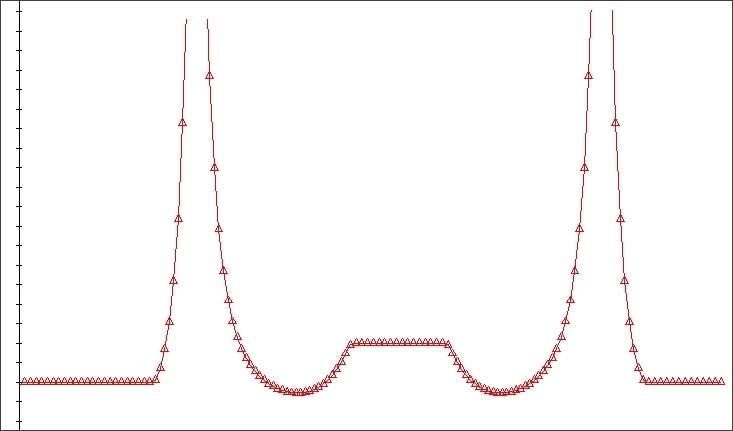

PRESSURE ANGLE and CAM Curvature

This

function display the Graphics of the Pressure Angle and Cam curvature

of the calculated Cam Profiles.

Graphic : PRESSURE ANGLE and CAM CURVATURE

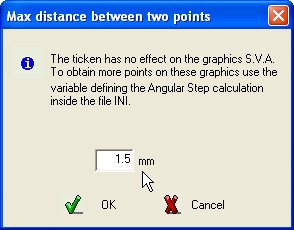

The function generates the thicken of the active Cam Profile

inserting new points belonging on the same spline.

The thicken

has no effect on the graphics S.V.A. To obtain more points on these

graphics use the variable defining the Angular Step calculation

inside the file INI.

Insert the value defining the max

distance between two adjacent points belonging on the Cam

Profile.

All the elements, having length grater than that defined,

are splitted in two or more parts.

SPECIAL

PROFILES (Intermittent Working)

This

menù includes all the commands allowing the definition of

Intermittent workings mechanisms.

These mechanisms don’t uses for the follower Cam basic curves,

therefore during the definition no graphic S.V.A. is represented.

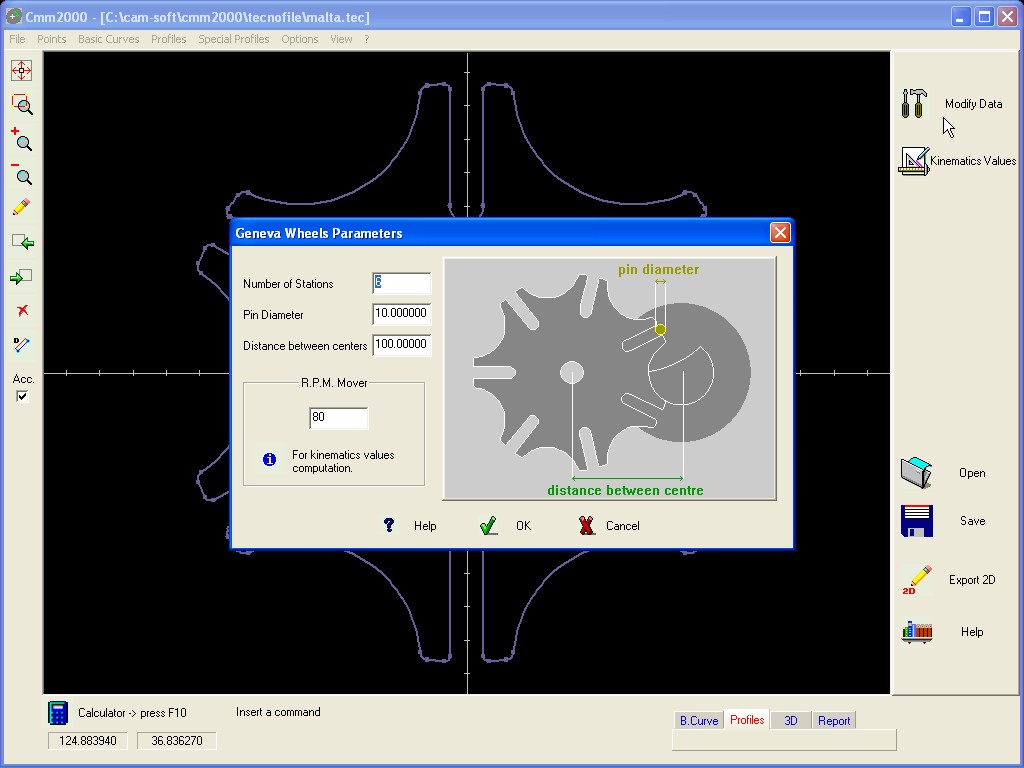

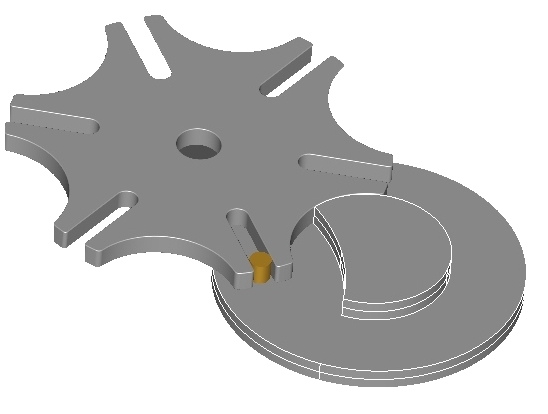

GENEVA WHEELS

For the definition the required Data

are :

Number

of Turnover station

Distance between centres of mover and Geneva

Wheel

Pin diameter

R.P.M. of the Mover.

The available Output are similar to these of the Cam.

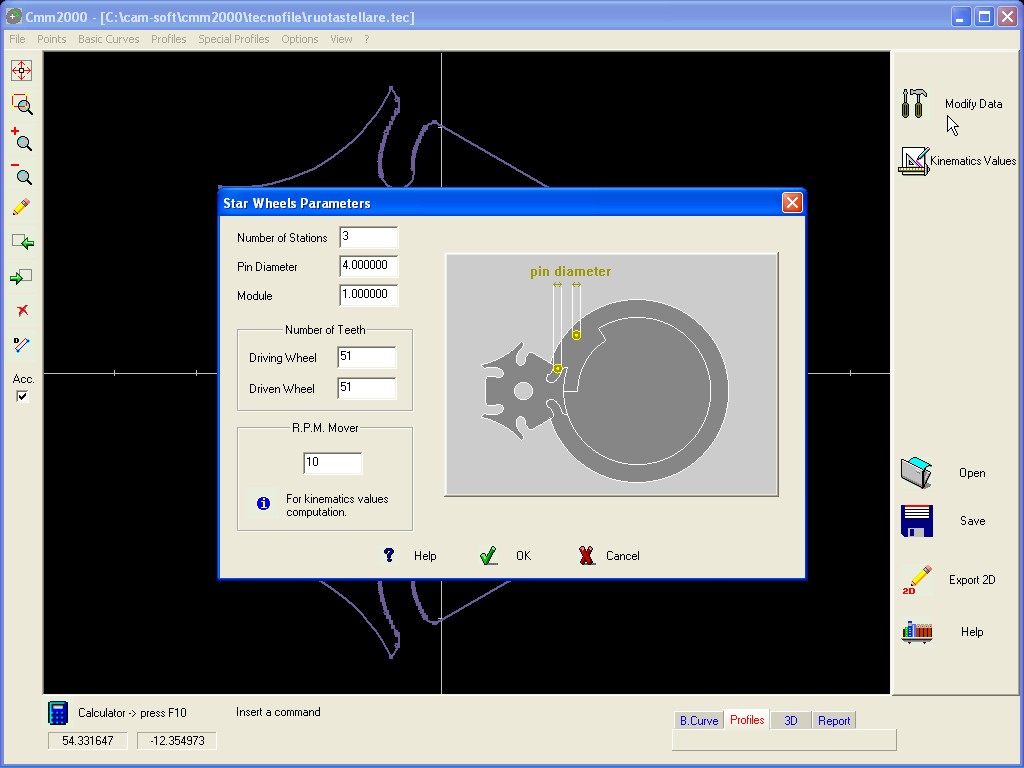

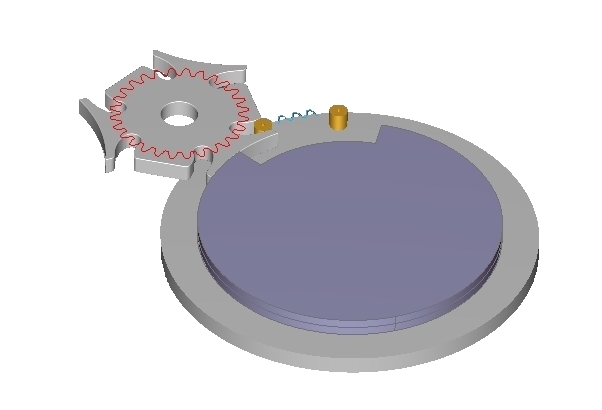

STAR WHEELS

The

working operation is like the Geneva Wheels it is added a couple of

gears.

For

the definition the required Data are :

Number of Turnover

station

Pin diameter

Module m0

Number

of Teeth for Z1

Number

of Teeth for Z2

R.P.M.

of the Mover

All the profiles necessary to the

mechanism

construction are completely defined.

The movements can be

simulated in the window 3D.

Inside the window Basic Curves it is possible to export the 2D

drawing in the format .DXF or .MI

The available Output are similar to these of the Cam.

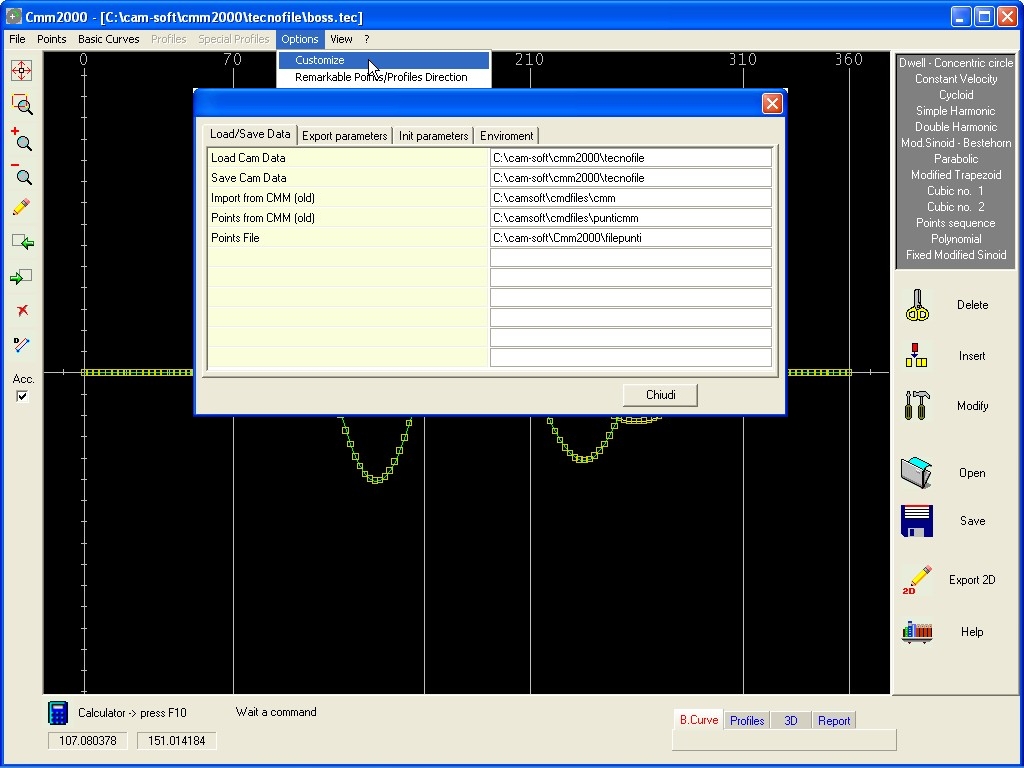

The following Options are available :

Enable

/ Disable the presentation of Remarkable points (vertex of

elements).

Enable

the configuration of the parameters inside File INI in order to

customize the program running.

As Maximum

Angular Step in

calculation and Max

Step Millimeter in

calculation,

important parameters in definition Cam Profile.

Variable inside the configuration file CMM2000.INI

defining the Max calculation angular

Step along

the Cam Profile.

Step Millimeter

Variable inside the configuration file CMM2000.INI

defining the Max calculation distance

[mm] between

two adjacent point, it change the max angular Step when it results

greater than the distance.

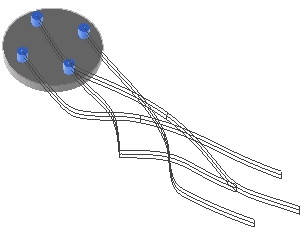

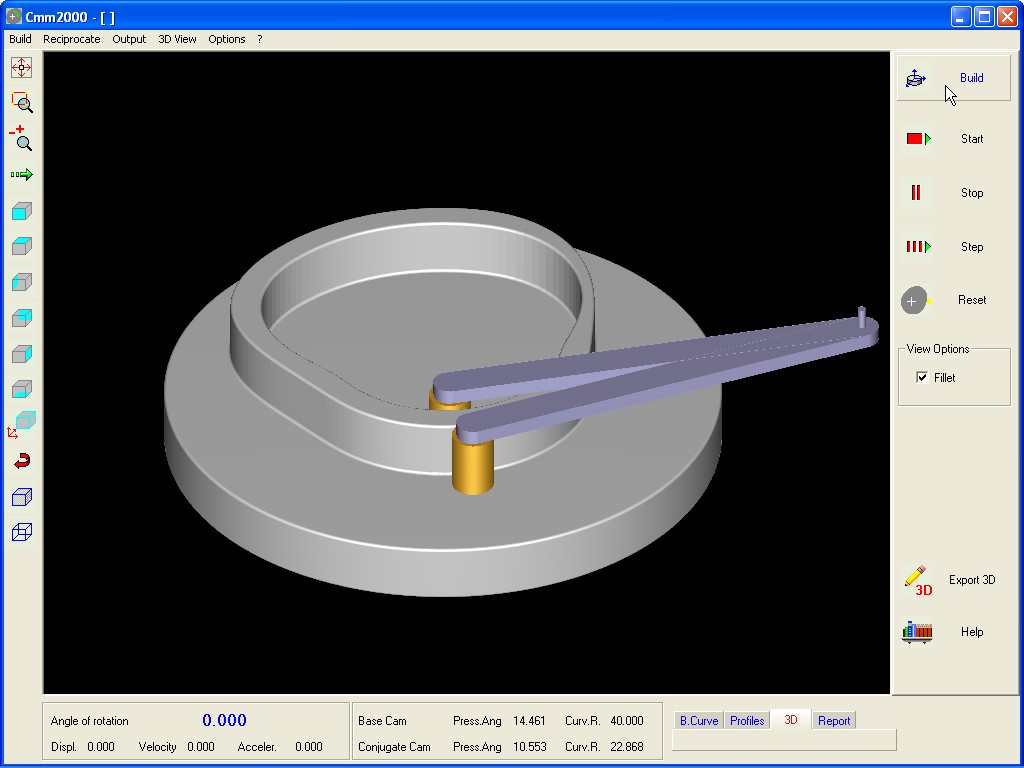

It operates the 3D visualization of processed Cam and simulates the Cam movement in respect to the defined Follower frame. Use the command to start / stop rotation , step to step rotation , return to start point and select, with standard command, the desired view.

In

order to select the part to be exported as file IGES

3D click

on the single part or in a group

keeping pressed

the key SHIFT.

Some

Option are available for the output :

PRINT

(window BASIC CURVES) Print the graphic S.V.A. in the current scale.

(window Cam PROFILES ) Print the drawing of the Cam Profile in the current scale.

(Menù Points – Top Bar) Print the

drawing of the, just loaded, File of Points in the current scale.

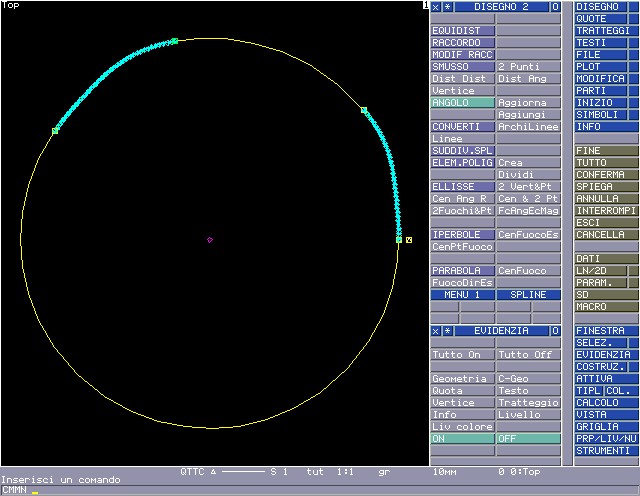

(window BASIC CURVES) export the graphic S.V.A. in the available format MI and DXF.

(window Cam PROFILES)

export the drawing of the Cam Profile in the available format MI

and DXF, or

create a new file of point reusable in CMM2000.

(window Cam PROFILES) saves a file Macro for CAD HP ME10 containing the B-SPLINE

The Macro Output can be directly made

from the

Menù File in ME10 or keystroking cmmn

corresponding to

the macro

loaded

during the start-up of the program.

DEFINE

Cmmn

LOCAL NAMEFILE

{This file '/CAM-SOFT/CMM2000/TMP/LAST' is automatically written by CMM2000 in manner to load the last Cam Profile generated}

OPEN_INFILE 1 '/CAM-SOFT/CMM2000/TMP/LAST'

READ_FILE 1 NAMEFILE

CLOSE_FILE 1

INPUT NAMEFILE

END_DEFINE

INPUT macro CMMN in ME10

INPUT macro CMMN in ME10

Conversion BSPLINE in

Circle-Arcs+Lines or

Lines inside ME10

Conversion BSPLINE in

Circle-Arcs+Lines or

Lines inside ME10

(window 3D)

save the object selected in the IGES

3D format.

In order to select

the part to be saved as file IGES

3D click

on the single part or in a group

keeping pressed

the key SHIFT.

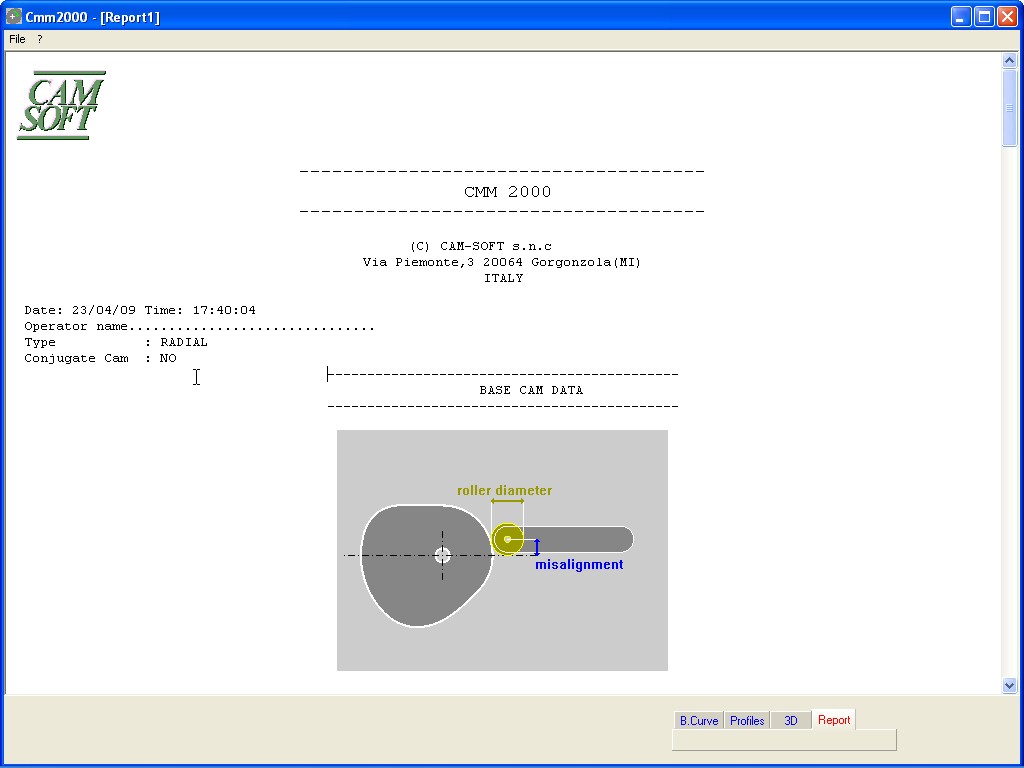

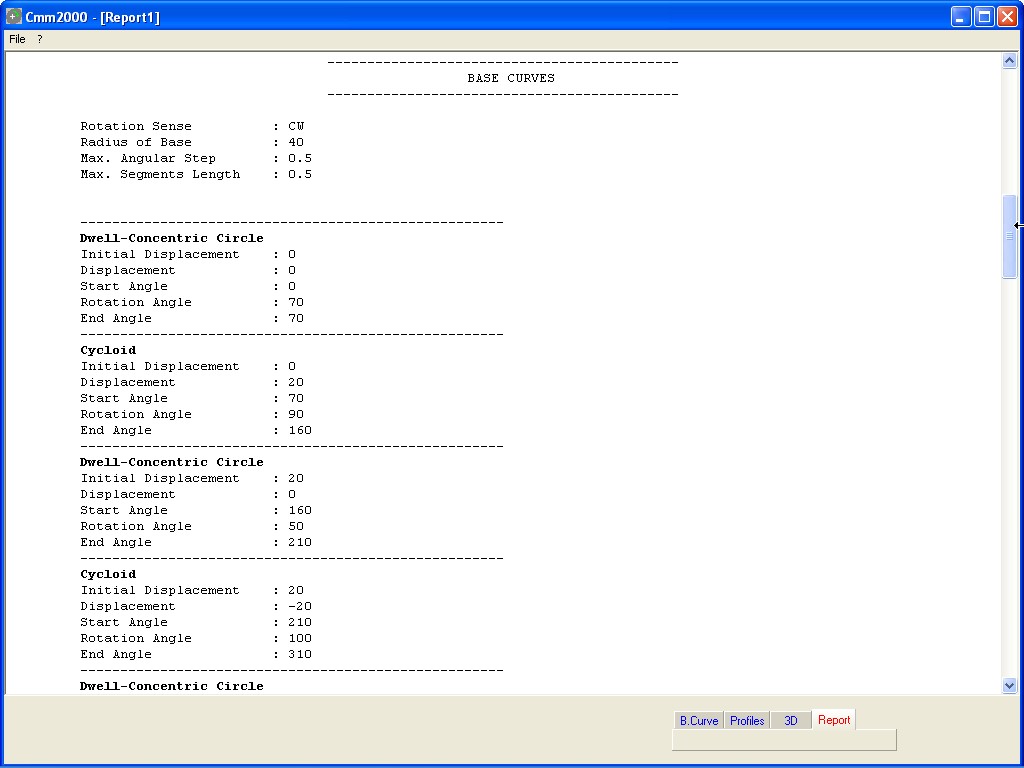

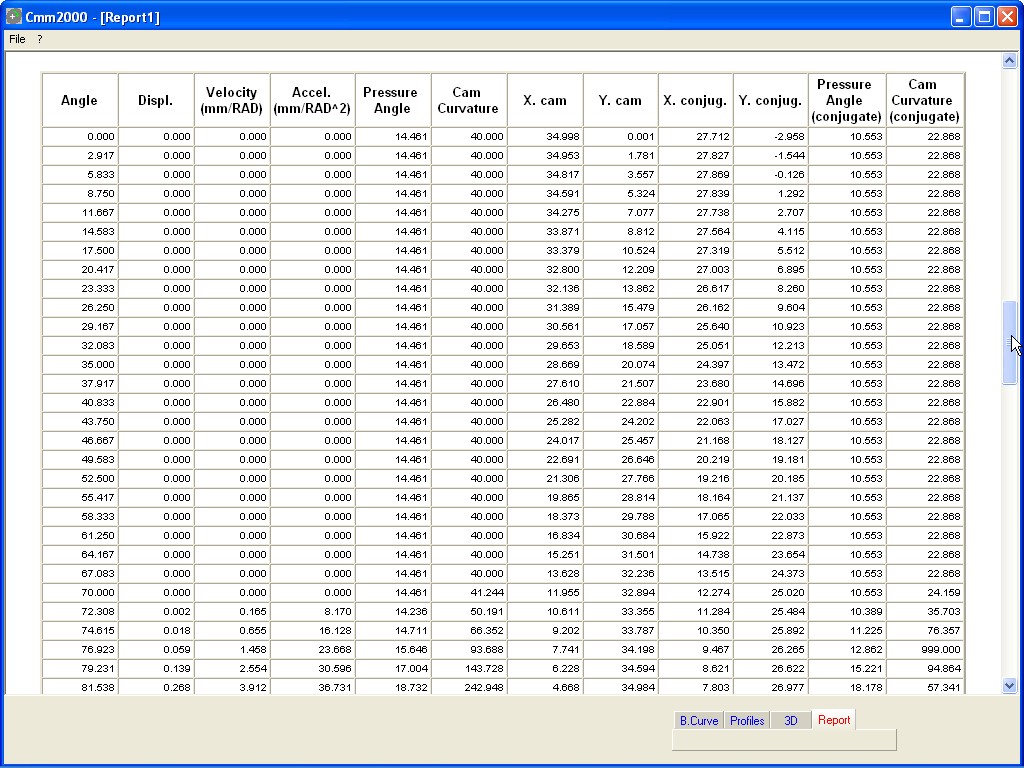

Gaining access to the window DATA, after generation of Cam Profile,

it is possible to visualize the summarizing data of the project.

It

is possible to optimize the HTML Report in order to store this file

all together the other useful files.

Inside Menù File (Top Bar) it is possible to select the command enabled to export Data in EXCEL format.

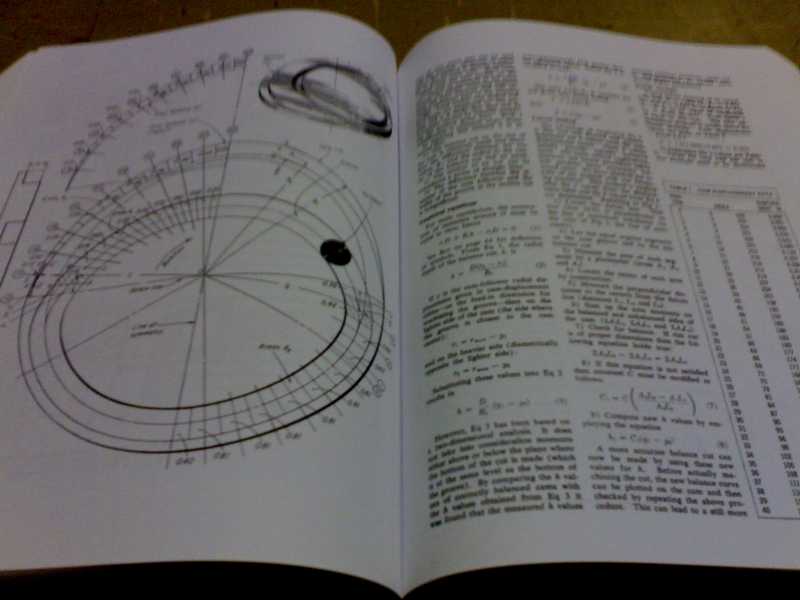

P. L. Magnani - G. Ruggieri ; "MECCANISMI PER MACCHINE AUTOMATICHE" Politecnico di Milano, Dipartimento di Meccanica ; UTET (Milano) 1986 H. A. Rothbart ; "CAMS DISIGN HANDBOOK" ; McGraw-Hill (New York) 2003

H. A. Rothbart ; "CAMS DISIGN, DYNAMICS AND ACCURACY " ; WILEY (New York) 1956

VDI-Handbuch Getriebetechnik I ; "BEWEGUNGSGESETZE FUR KURVENGETRIEBE, Theoretische Grundlagen" VDI 2143 Dusseldorf 1980

SOFT-MEC ; "MECAD Mechanisms Computer Aided Design" ; Hadbook - University of Brescia 1991

Return at Home page.

Return at Home page.