|

PGL2000 -

easy, powerful and flexible

CS

PGL2000 is

an application software producing powerfull advanced functionality for

automatic programming and simulation system for Numerical Control

Machines.

The

interpretation of more common CAD formats

like MI, DXF, IGES 2D enables the quick bridge from

the mechanical drawing to the CNC File for machining.

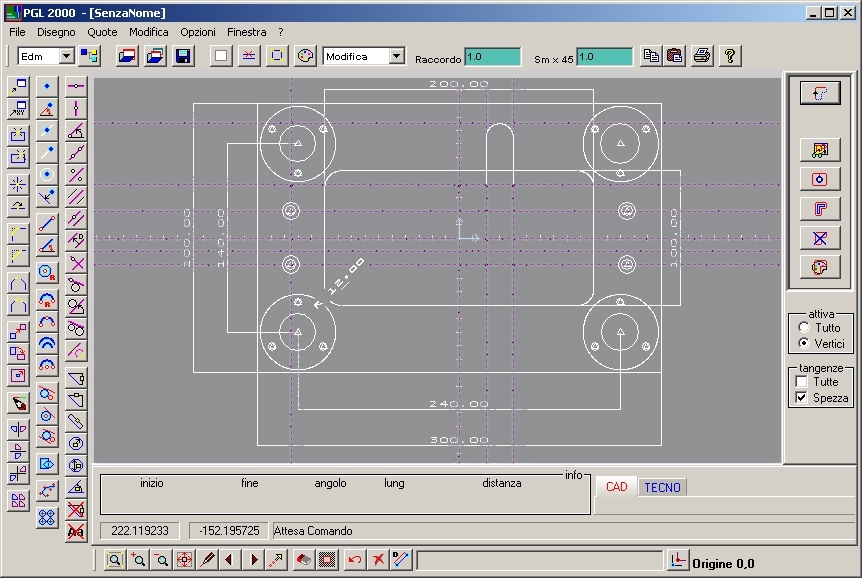

The

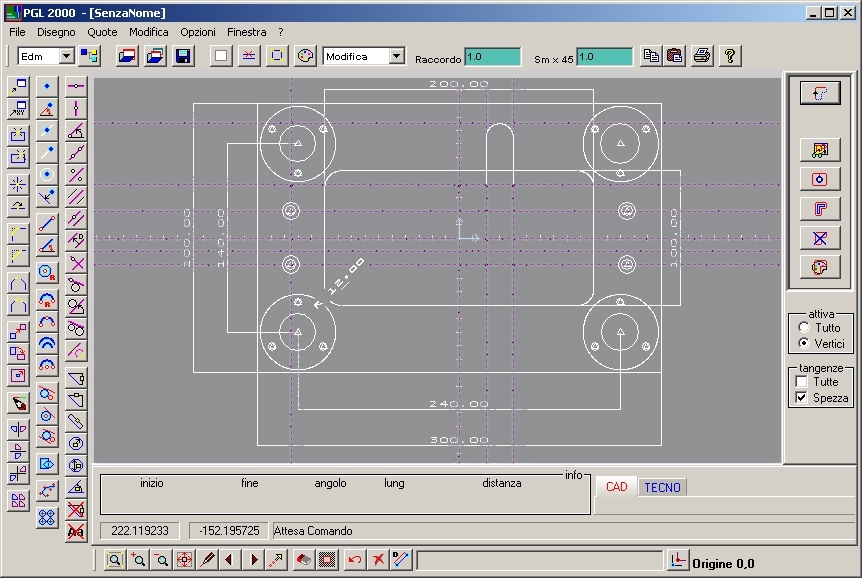

geometric window displies the loaded files and enables the commands to

modify and optimize the drawing, the geometric window is also enabled

to define further independent geometry from the CAD.

Some commands:

- Introduction of new

geometry (ie: fillets, points, segments, arcs and so on; definition

of new profiles not acquired from cad).

- Positioning of the zero

working (also for different parts simultaneously loaded).

- Clearing of unnecessary

geometry and management of the active colours.

- Repetitions with

positioning and rotation.

- Correction of tangency

problems using the commands trim, cut, extend.

- Immediate automatic

generation or recognition of canonics profiles (slots, polygons and

so on).

- Automatic recognition of

holes diameter and position.

- Dangerous superposed

elements clearing.

- Dimensions insertion to

complete the drawing.

- Distances check to

confirm the tool access capability.

- Many other facility to increase operator

productivity.

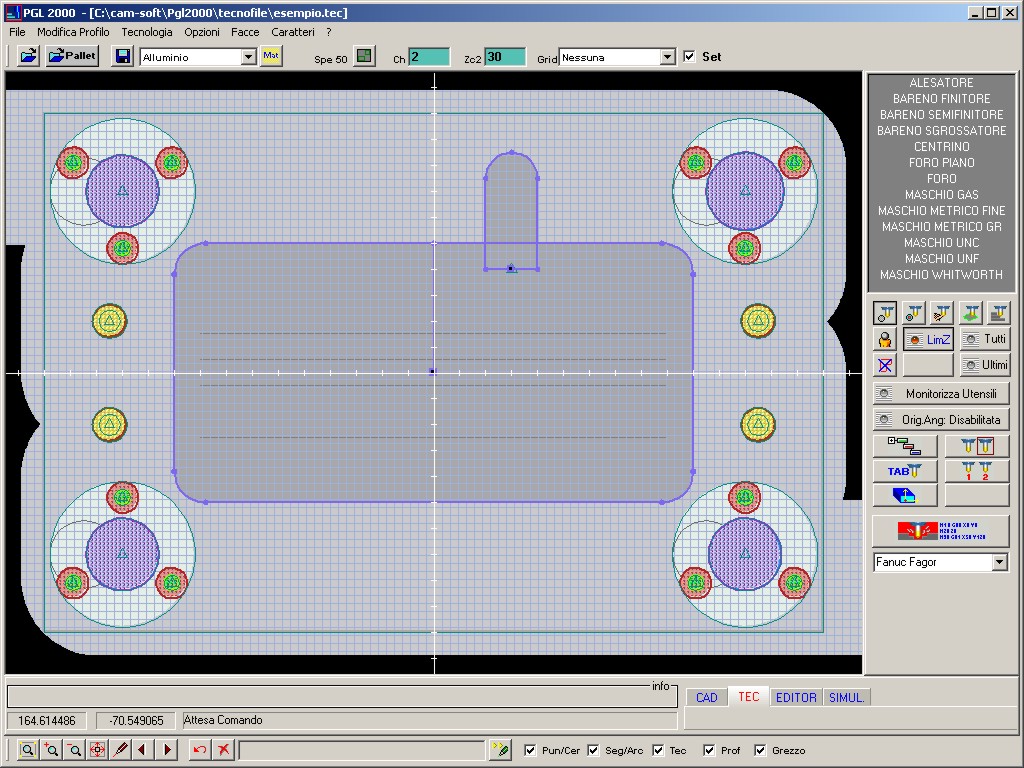

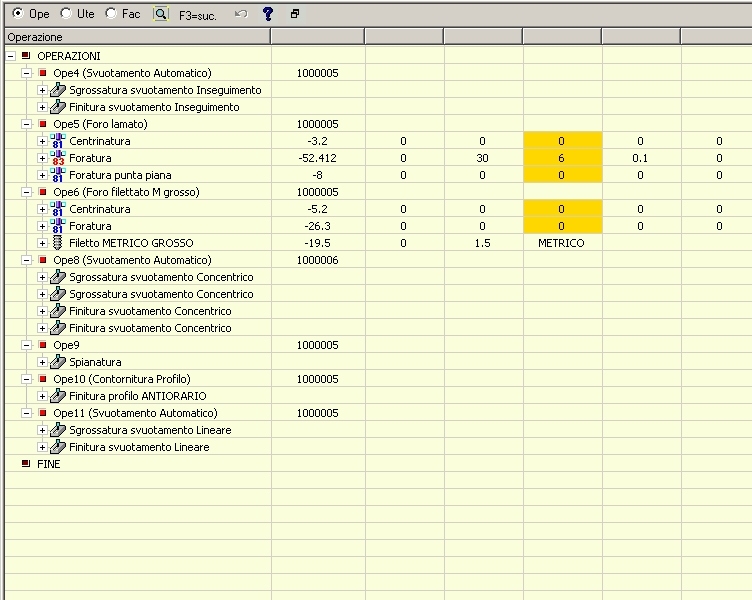

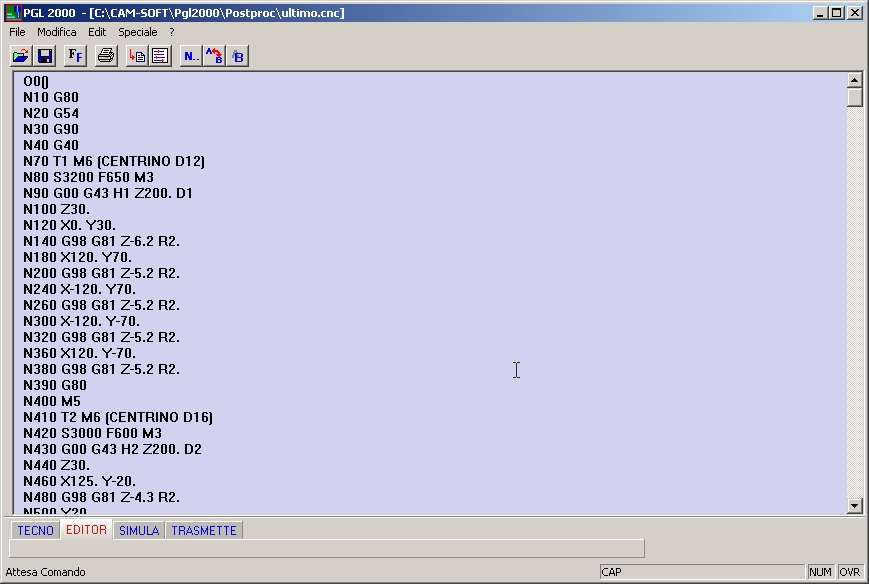

The technological window displies the geometry and enables the application of the technologic strategies.

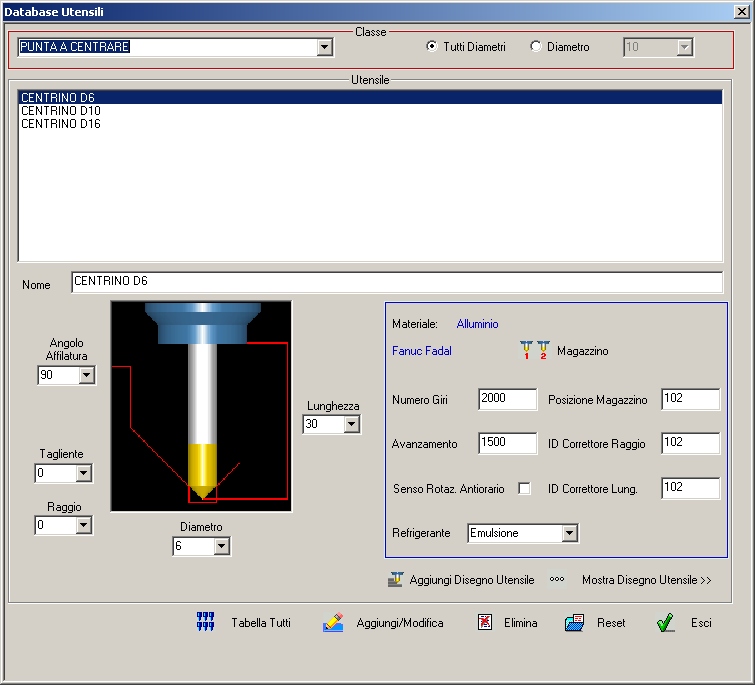

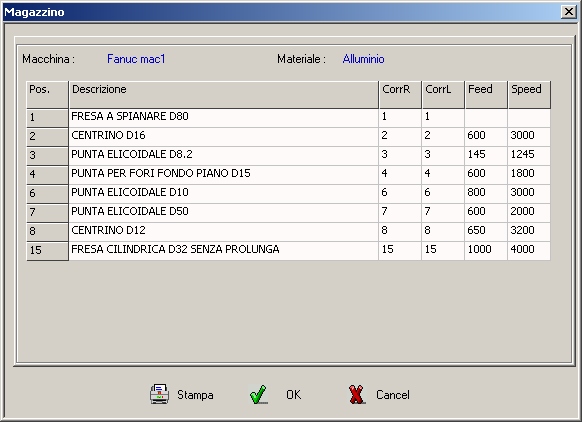

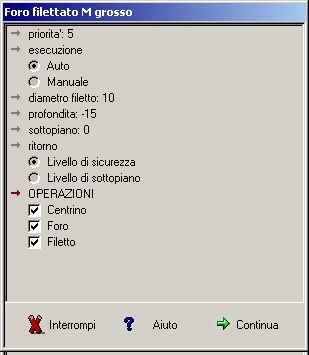

- Three definition level of

technology for drilling and milling:manual control, simple

instructions control and automatic control.

- 2D and 3D milling.

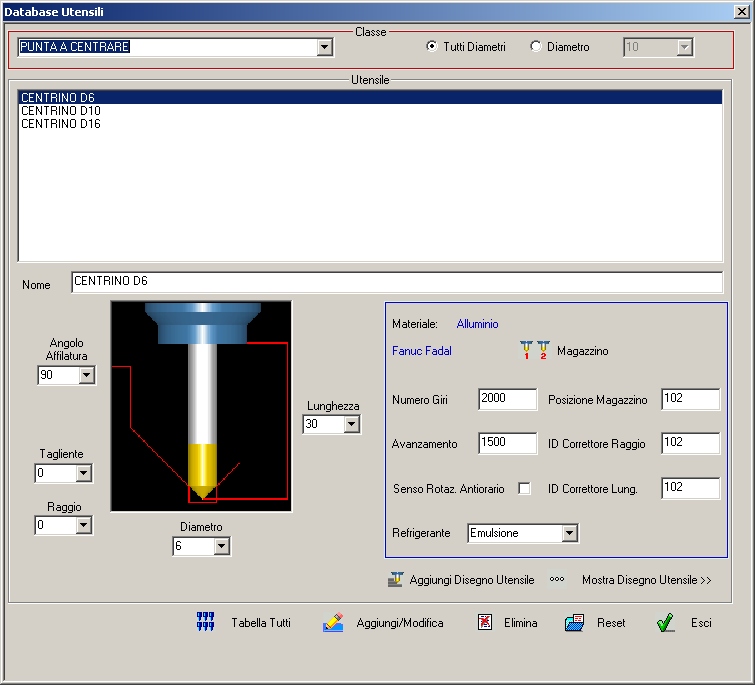

- Material selection and automatic assignement of technological

cutting parameters:

- from pre-defined tool in database

- from

technological table

-

Machine tools

crib management.

- Interctive

visualization of generated CN file concerning the current status of

job.

- Second safety

level definition (obstacle and bracket step over).

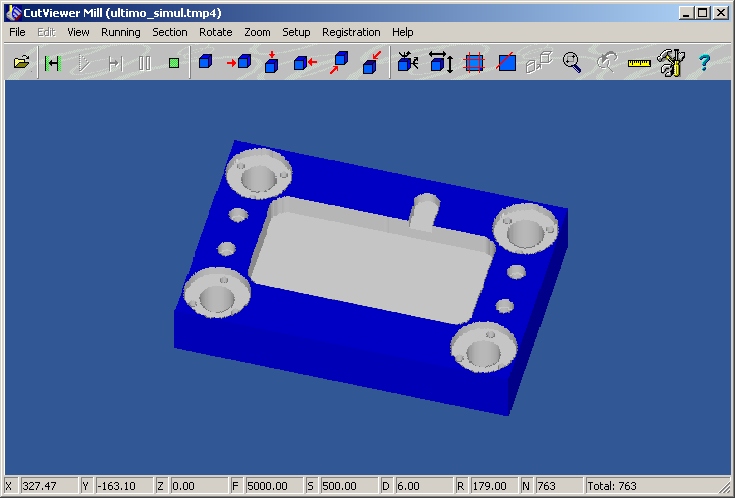

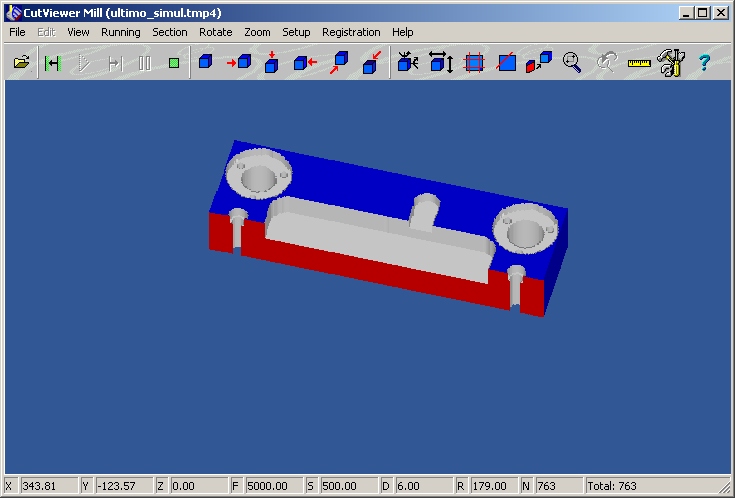

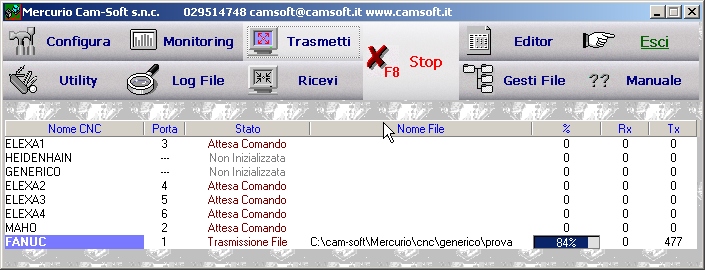

- CNC machines

simulation removing material from stock in true solid modeling.

- Pallet management.

- Rotating axe management (4th axe) continuous movement or indexed.

- Rotating head (5th axe).

No more complex calculation routines for the operator: - Definition of no-quoted points

- Computing of center tool path

- Shrink material effects

- Secondary level of the workplane management in respect to the Z base.

|

Return at Home page.

Return at Home page.